Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

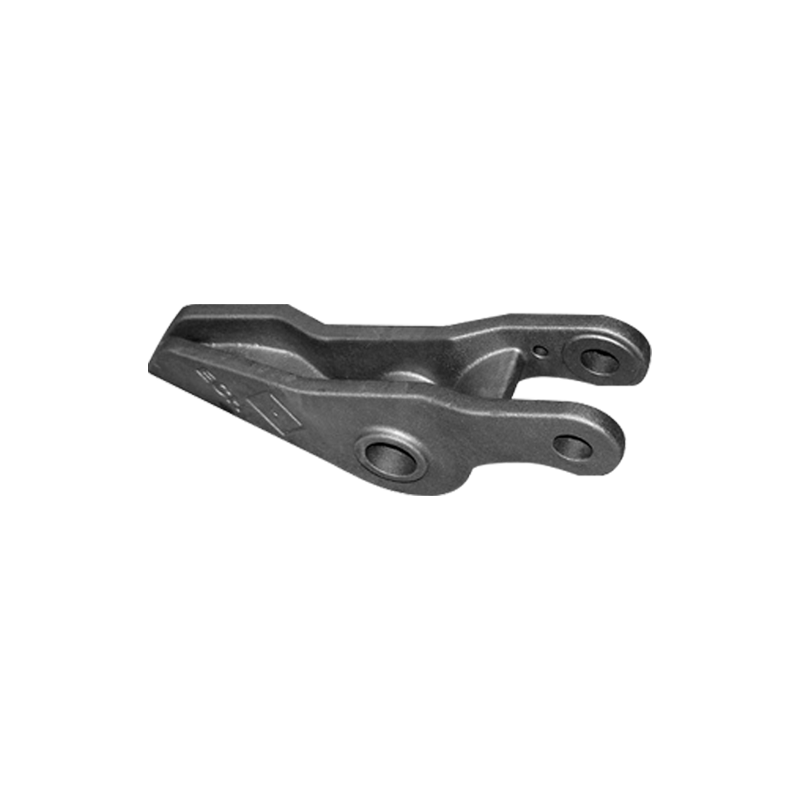

1. Material properties

The material of 105KG Marine Dock Casting Steel Hook is usually high-strength alloy steel, which is widely used in various heavy-duty equipment due to its superior mechanical properties. The main advantage of alloy steel is its high tensile strength and toughness, which allows it to withstand large loads without being easily deformed or broken. During the casting process, the molecular structure of the steel is carefully optimized to ensure its stability and safety in high-pressure environments. High-quality alloy components such as manganese, nickel and chromium can improve the overall strength and wear resistance of steel. In practical applications, this material enables the hook to maintain stable performance in complex working environments, especially the moisture and impact forces frequently encountered in the ocean, greatly reducing safety hazards caused by material fatigue.

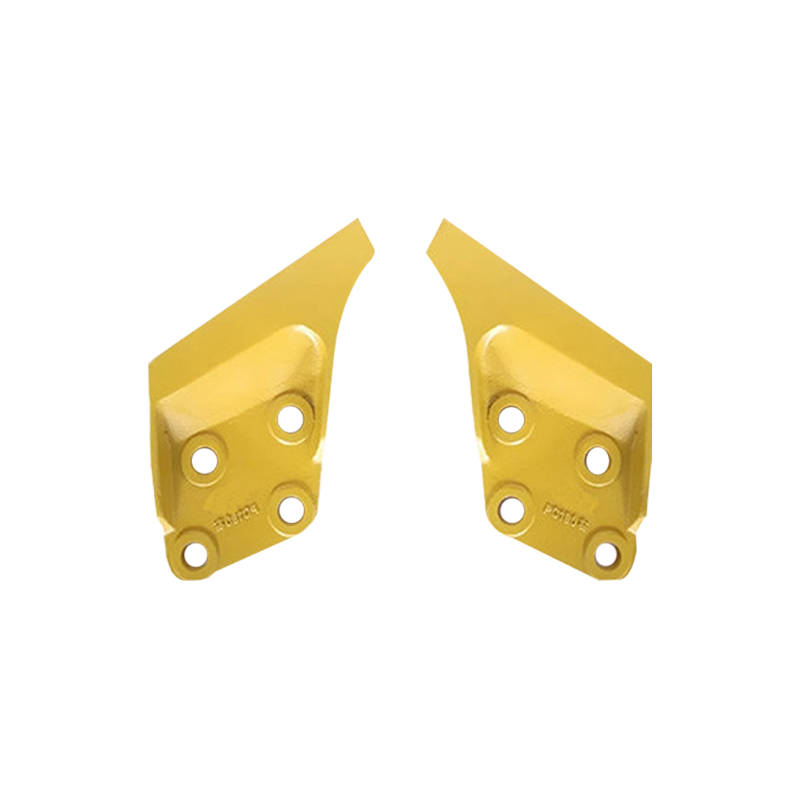

2. Corrosion resistance

In a marine environment, salt water and high humidity have a significant impact on the corrosion of metal materials, especially ordinary steel. Therefore, in order to improve the corrosion resistance of 105KG Marine Dock Casting Steel Hook, many manufacturers will use a variety of anti-corrosion technologies. Common treatments include hot-dip galvanizing, spraying polymers or using stainless steel. These treatments effectively block moisture and oxygen, preventing rust and corrosion from occurring. For example, galvanizing not only provides a physical barrier but also increases surface hardness and improves wear resistance. Manufacturers may consider drainage and ventilation in the hook design to further reduce moisture retention and avoid exacerbating rust problems. Through these anti-corrosion measures, the service life of the hook is extended, ensuring its continued performance in harsh environments.

3. Load capacity

The load capacity of the 105KG Marine Dock Casting Steel Hook is one of its most important performance indicators. The nominal 105kg load capacity indicates the hook's safe load limit under normal operating conditions. However, in actual applications, the hook's load capacity may be affected by a variety of factors, including environmental conditions, uniform distribution of the load, and operator usage. In actual operations, the manufacturer's instructions must be followed to avoid overload operations to reduce potential safety risks. Dynamic changes in load will also affect the load-bearing capacity of the hook, so when lifting heavy objects, you should ensure that the load is stable and avoid sudden impacts and swings. Through proper load management and use, the strength and stability of the hook can be fully utilized to ensure safety when lifting and securing boats, thereby effectively preventing damage or accidents caused by overloading.

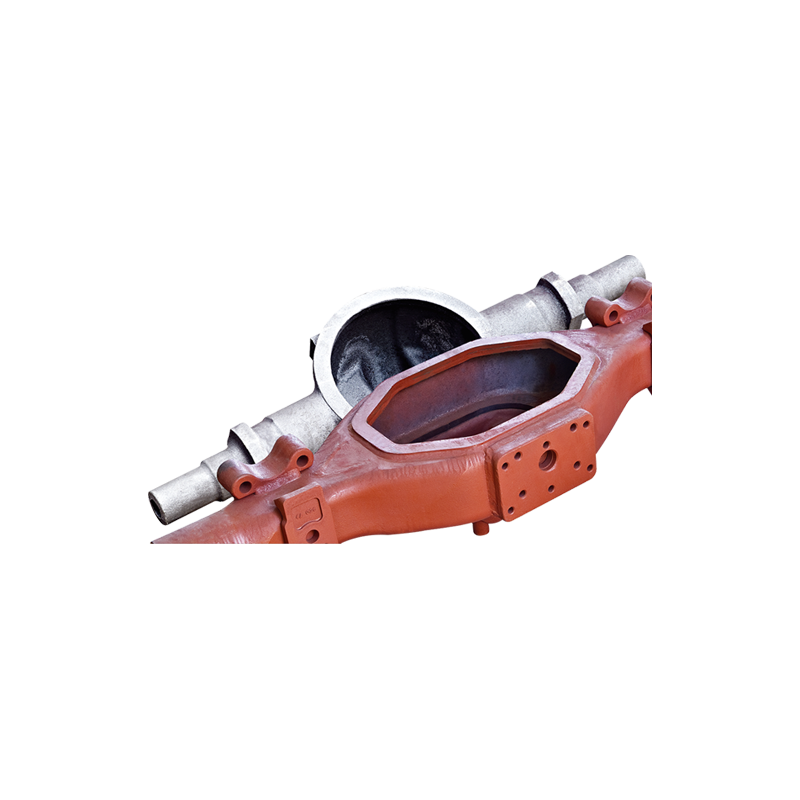

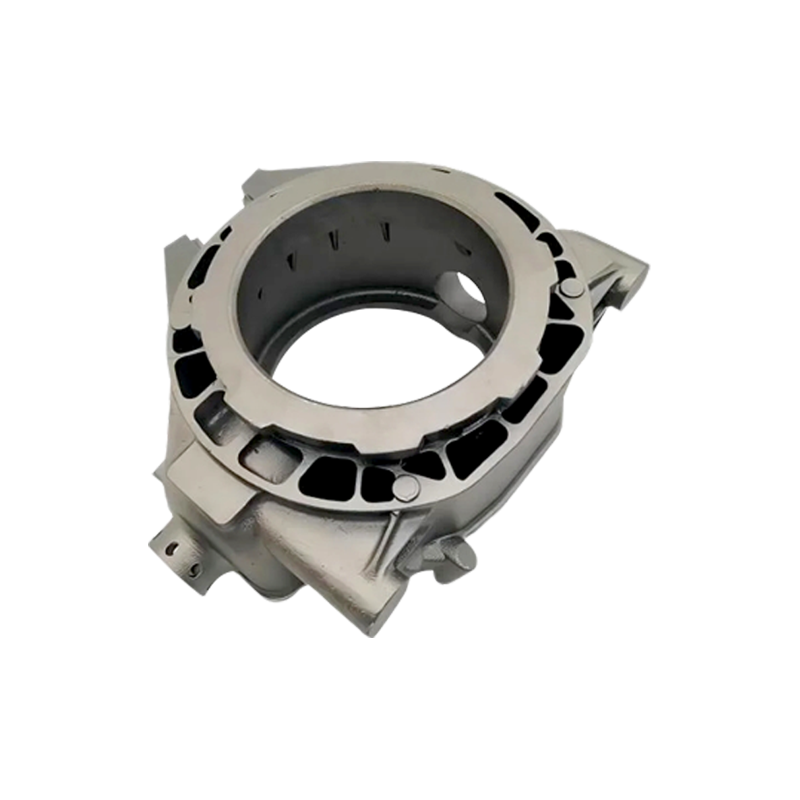

4. Structural design

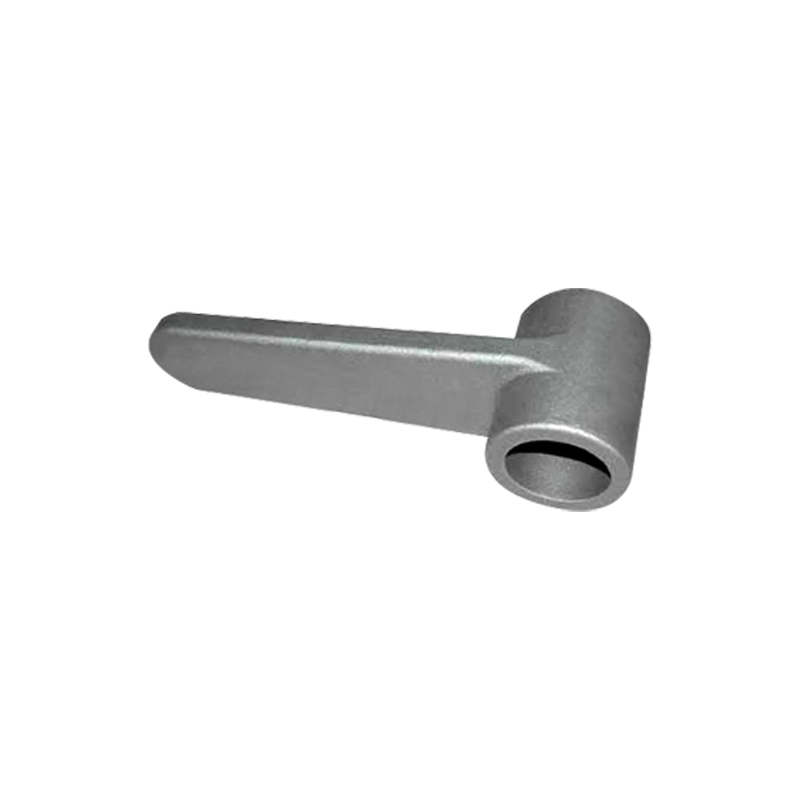

The structural design of the hook is critical to its strength and durability. The design of the 105KG Marine Dock Casting Steel Hook has undergone rigorous engineering calculations to ensure that it remains stable under different load conditions. During the design process, manufacturers usually use computer-aided design (CAD) technology to simulate the force conditions of the hook in actual use for optimization. For example, the curves and connecting parts of the hook are specially designed to disperse the force exerted on the hook and avoid local stress concentrations, thus reducing the risk of breakage. Hooks are generally designed to adapt to a variety of working angles and can flexibly respond to different lifting needs. Good structural design can also reduce the complexity of installation and disassembly and improve the convenience of operation. When selecting a hook, users must pay attention to its design details to ensure that the selected hook meets specific usage requirements and achieves optimal performance.

5. Use and maintenance

Use and maintenance are key factors in ensuring the durability and strength of the 105KG Marine Dock Casting Steel Hook. Even the best quality hooks can develop problems during use if they lack proper maintenance. Regular inspection of hooks for wear and corrosion is crucial, especially in marine environments where hooks can be attacked by salt and moisture. Users are advised to clean the hooks regularly to remove dirt and salt, and apply anti-rust oil or other protective agents when necessary. Also, check connections and hinge points to make sure there are no signs of looseness or damage. In actual operation, the manufacturer's instructions for use should be strictly followed to avoid overloading or improper use. Storing your hook properly when not in use and avoiding exposure to moisture or extreme weather conditions will not only extend the life of your hook, but also ensure it is in top condition when you need it. Through these meticulous maintenance tasks, the performance and safety of the hook can be maximized.

Language

Language

FT CASTING

FT CASTING