Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

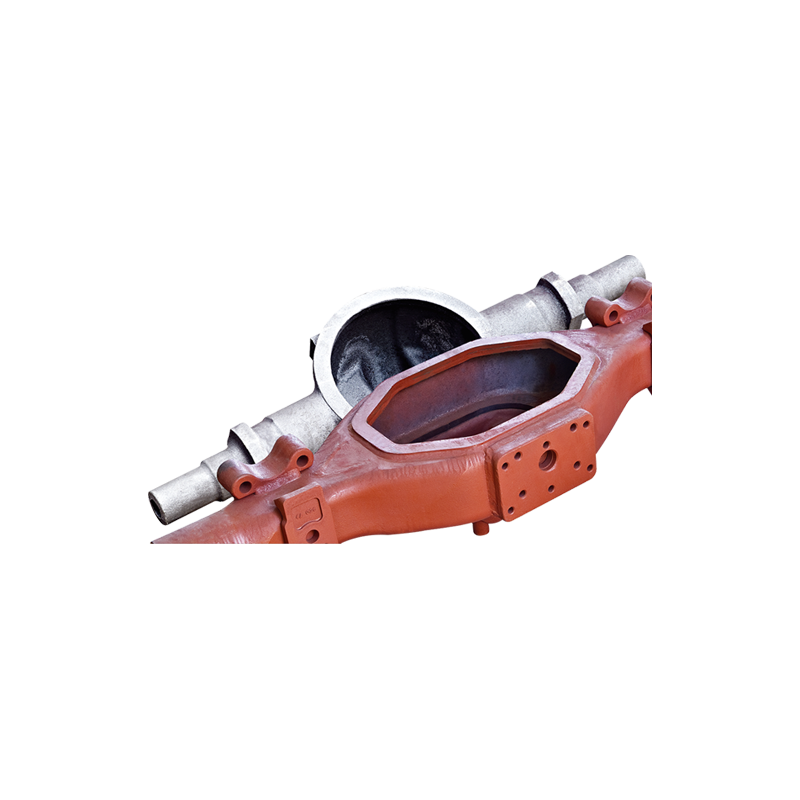

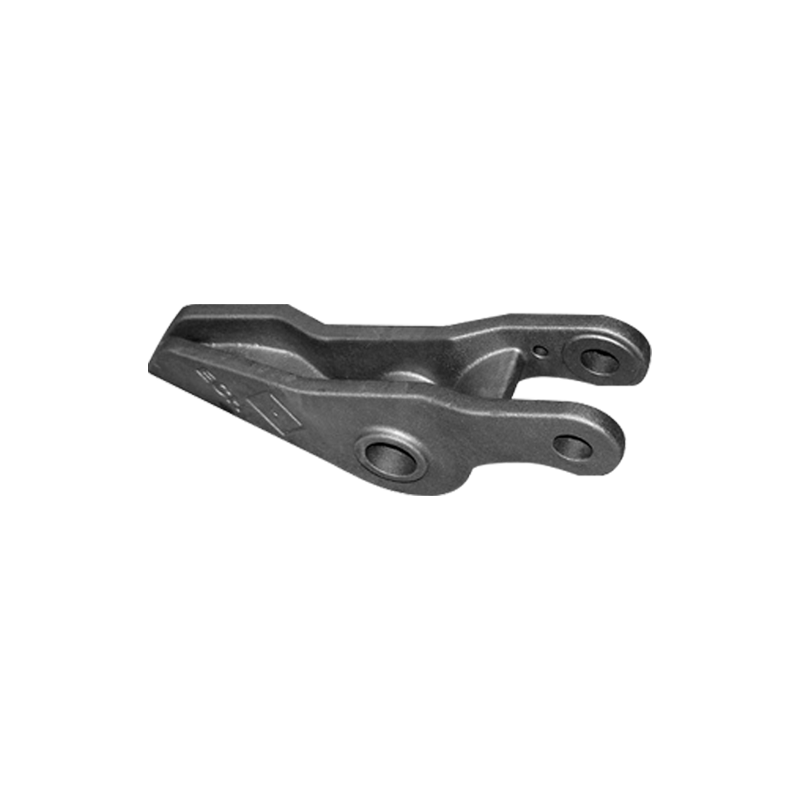

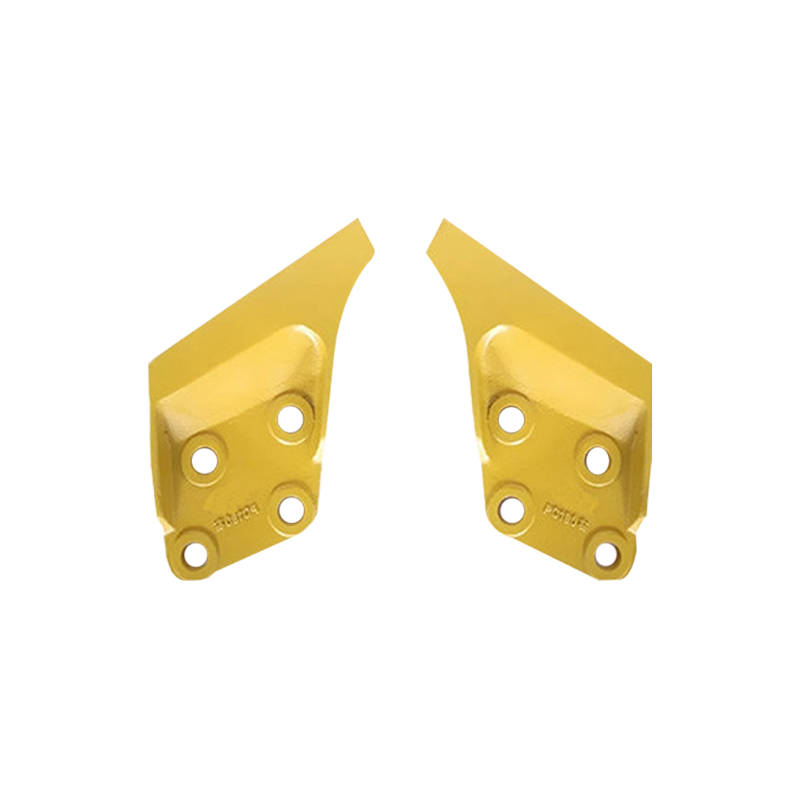

Automobile&Truck Casting Steel Parts

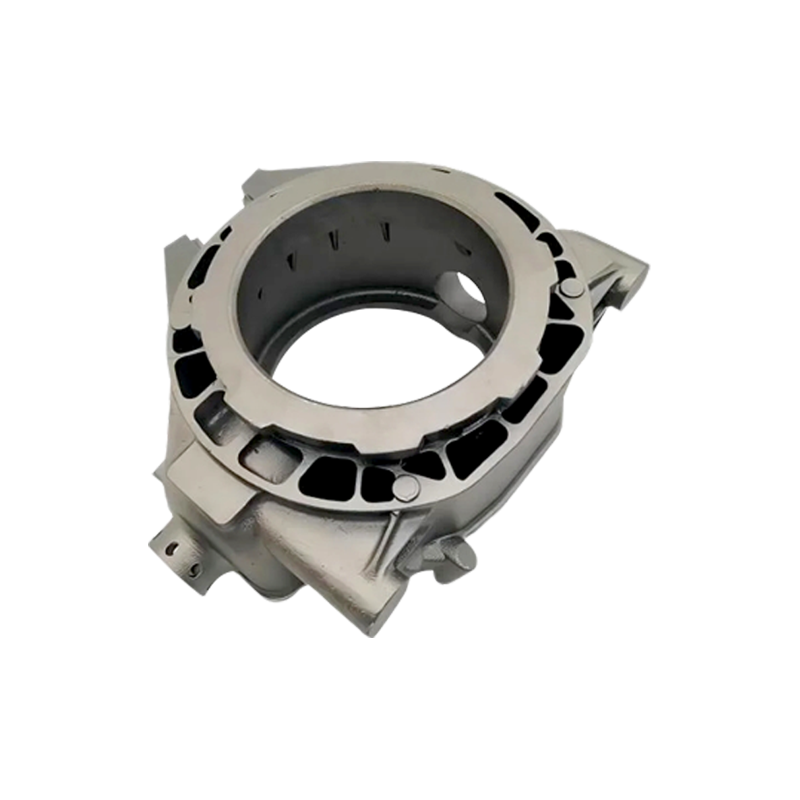

CNC Machining Car Exhaust Manifold

The exhaust manifold is a piping system connecting the engine cylinder block to the exhaust manifold, channeling exhaust gases from each cylinder into the exhaust manifold. Its core function is to reduce exhaust resistance and prevent cross-interference between exhaust gases from different cylinders, thereby ensuring efficient and smooth engine operation.

Material Characteristics

Cast iron and stainless steel are the mainstream manufacturing materials. Cast iron is relatively low-cost, making it suitable for controlling vehicle manufacturing costs; stainless steel is lightweight and highly resistant to high-temperature corrosion, and is often used in high-performance vehicles to reduce exhaust resistance.

Design Key Points

Structure: A branched piping design is employed, typically with one branch per cylinder or two cylinders, to prevent cross-interference caused by concentrated exhaust emissions.

Performance: A balance must be taken between engine power, fuel economy, emission standards, and vehicle layout.

Language

Language

FT CASTING

FT CASTING