Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

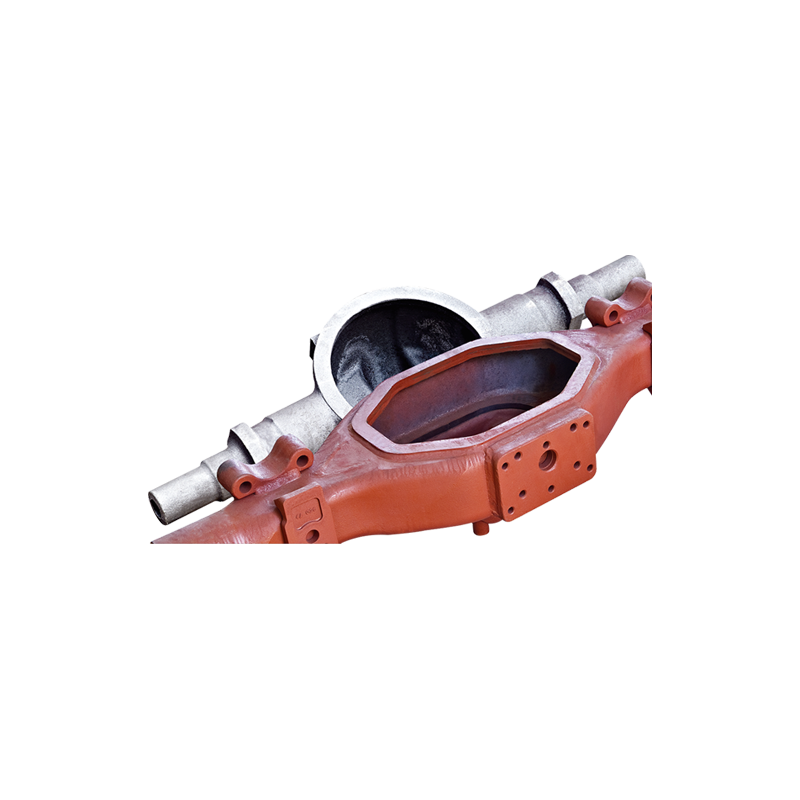

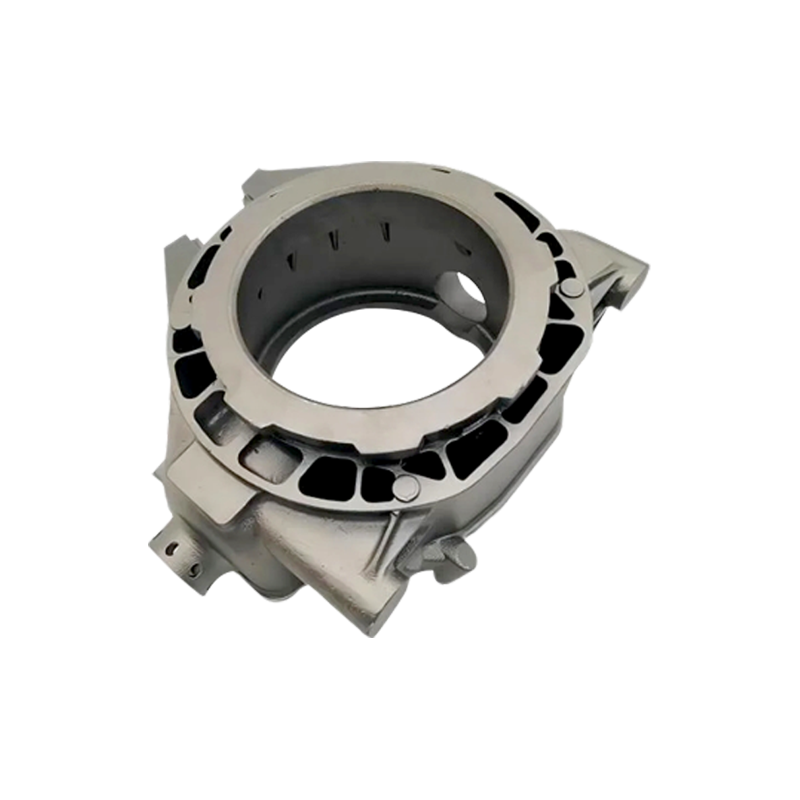

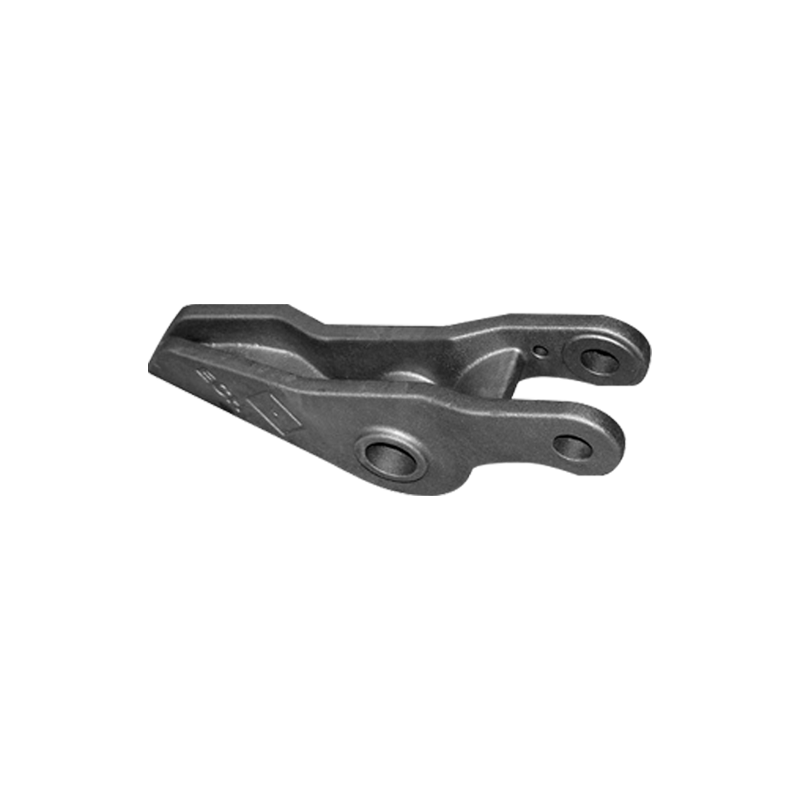

Engineering Machinery Casting Steel Parts

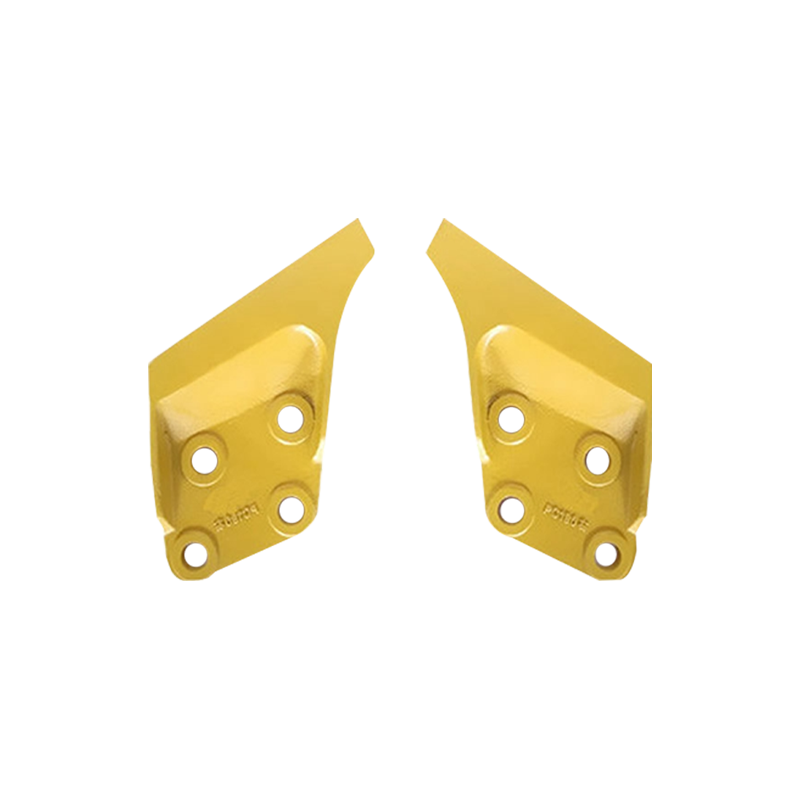

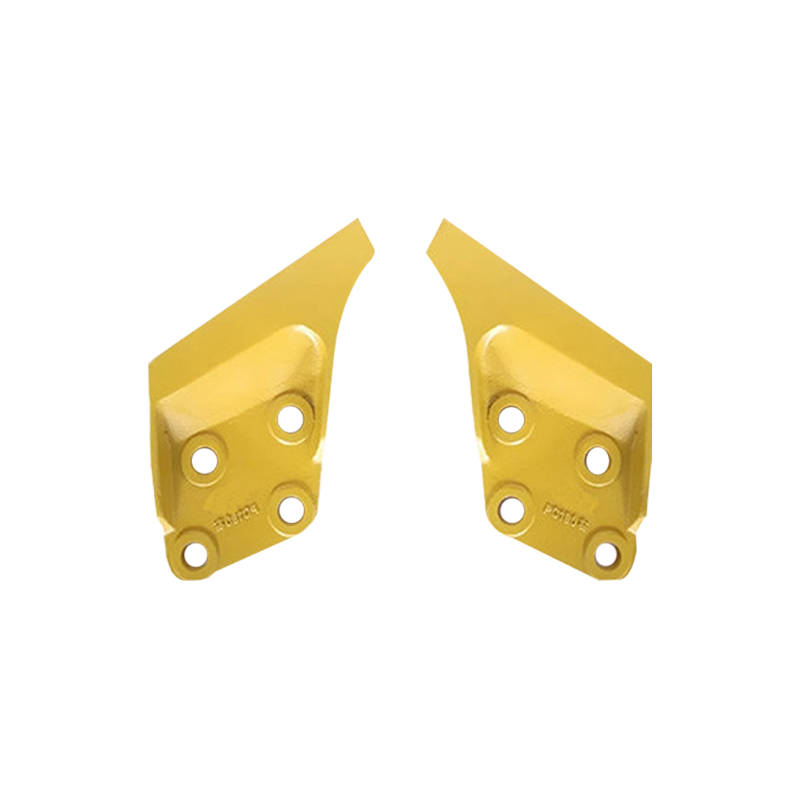

Steel Casting Mini Excavator Bucket Side Cutter

The blade is a component used in construction machinery for cutting and shoveling materials. It is mainly installed on the bucket of loaders, bulldozers and other equipment. It cuts into materials through the sharp edge and completes the loading operation.

Material and structure

The blade plate is usually made of high-strength wear-resistant steel (such as medium manganese alloy steel) or alloy materials, and some models are heat treated to enhance wear resistance and impact resistance. The structure is mostly straight or V-shaped, and some toothed structures can adapt to different working conditions.

Functions and types

Straight integral blade: suitable for loose materials (such as sand, gravel).

V-shaped integral blade: suitable for hard materials (such as rocks).

Toothed blade: Enhances cutting efficiency and is the most widely used.

Application scenarios

It is mainly used in the bucket part of construction machinery such as loaders and bulldozers. It is responsible for cutting into material piles and pushing materials, such as soil, sand and gravel, coal, etc.

Language

Language

FT CASTING

FT CASTING