Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

1. Superior Strength and Durability

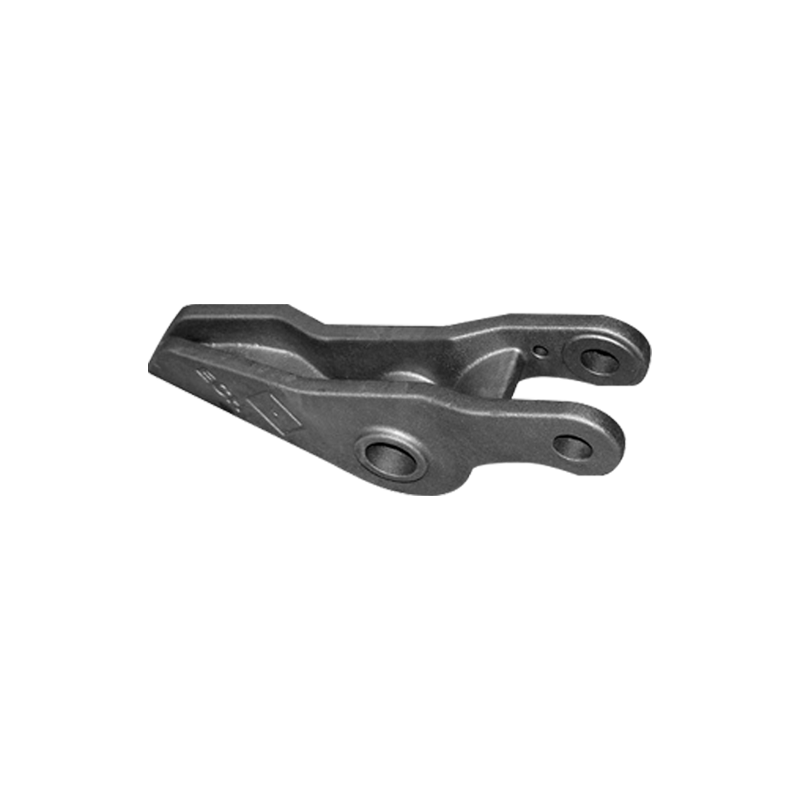

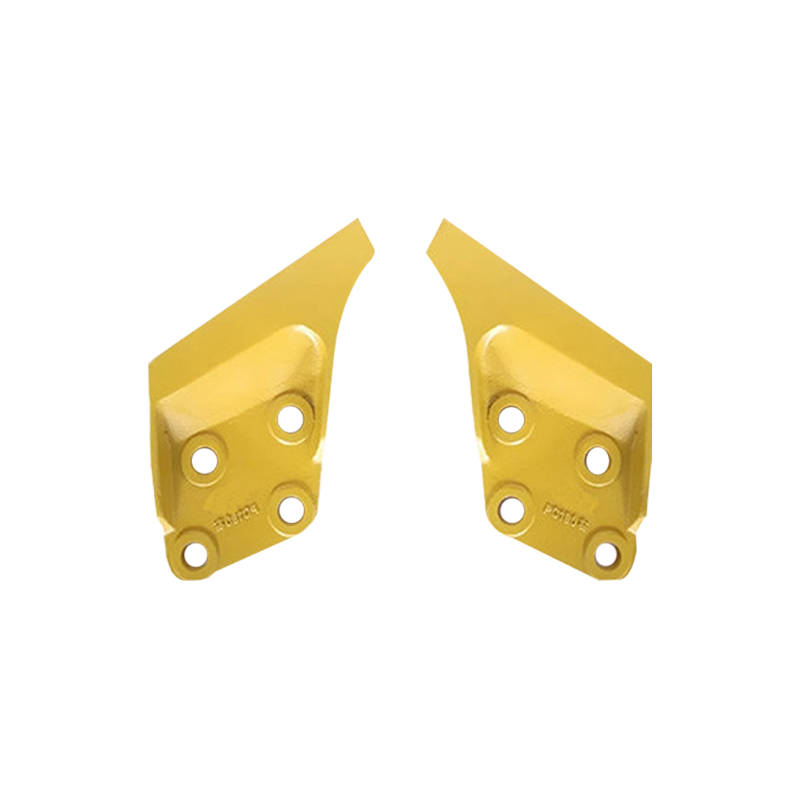

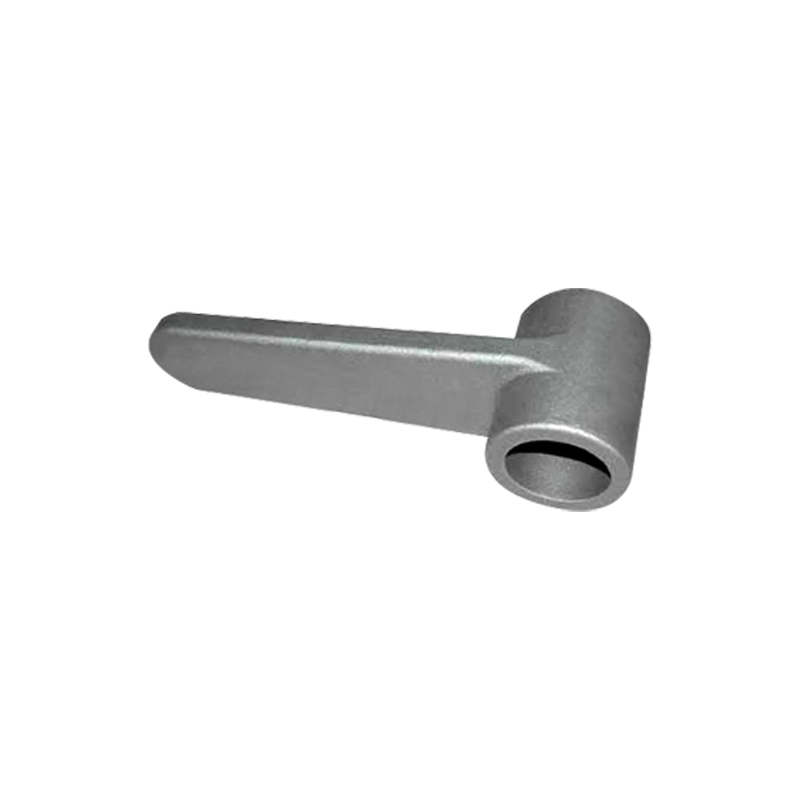

One of the primary reasons casting steel parts are widely used in automobiles and trucks is their exceptional strength and durability. Steel is renowned for its high tensile strength, which allows it to withstand significant stress, pressure, and heavy loads without deforming or breaking. In applications such as trucks, which often carry heavy cargo and are subject to rigorous conditions, using cast steel parts ensures that critical components, like suspension systems, axles, and chassis parts, can handle these demands without failure. The casting process itself further enhances the durability of these parts by allowing for the creation of dense, homogenous material structures, minimizing internal weaknesses. This durability results in longer-lasting components, reduced maintenance costs, and improved overall vehicle reliability, making steel castings essential for both everyday automobiles and heavy-duty trucks.

2. Design Flexibility and Complexity

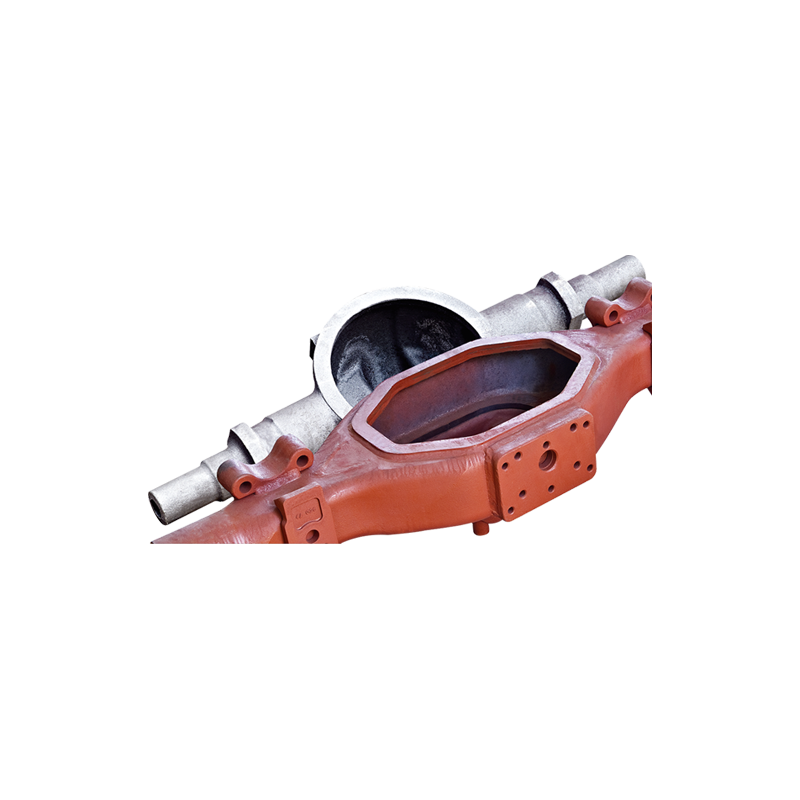

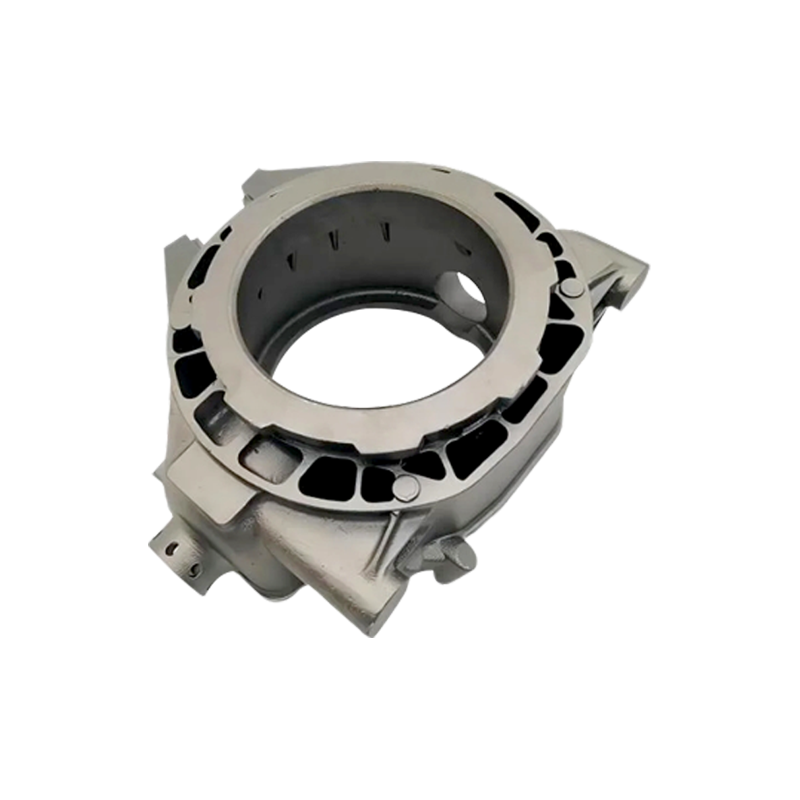

Casting steel parts offer immense design flexibility, which is a significant advantage for automakers. The casting process allows for the production of complex shapes and geometries that would be difficult or impossible to achieve with other manufacturing methods like forging or machining. This flexibility is particularly beneficial for modern vehicles, where components need to be both lightweight and strong to improve fuel efficiency and performance. With casting, engineers can create intricate designs that combine different features into a single part, reducing the need for additional welding or assembly. This not only simplifies production but also improves the overall structural integrity of the vehicle. In trucks, for example, casting enables the manufacture of parts like engine blocks, transmission cases, and differential housings, all of which have complex shapes but require high strength and precision.

3. Cost-Effectiveness and Efficiency in Mass Production

Automobile&Truck Casting Steel Parts is a highly efficient and cost-effective process, especially when producing parts in large quantities. The ability to produce multiple identical parts from a single mold reduces both production time and material waste. This is particularly advantageous for the automotive and trucking industries, where large-scale manufacturing is standard. Once the mold is created, casting steel parts can be reproduced quickly and with high precision, leading to economies of scale. The strength and durability of steel reduce the need for frequent replacement of parts, contributing to lower long-term maintenance costs. The recycling capability of steel adds to the cost-effectiveness, as unused or scrapped materials can be melted down and reused, reducing overall material costs and environmental impact. Thus, for both mass production and aftermarket components, casting steel parts offer an optimal balance between quality and cost-efficiency.

Language

Language

FT CASTING

FT CASTING