Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

1. Precise processing capabilities of complex geometric shapes

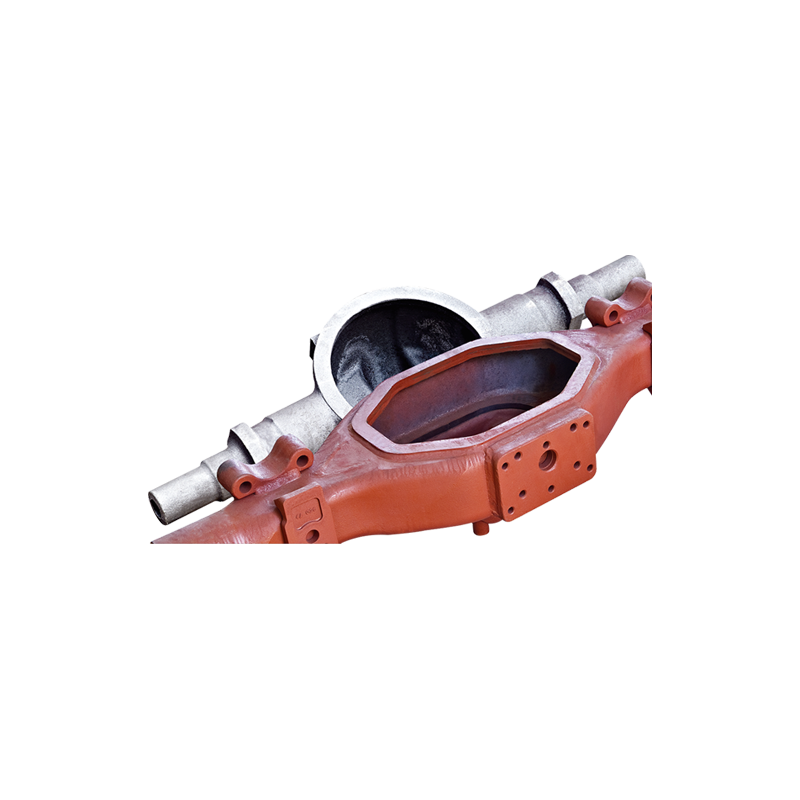

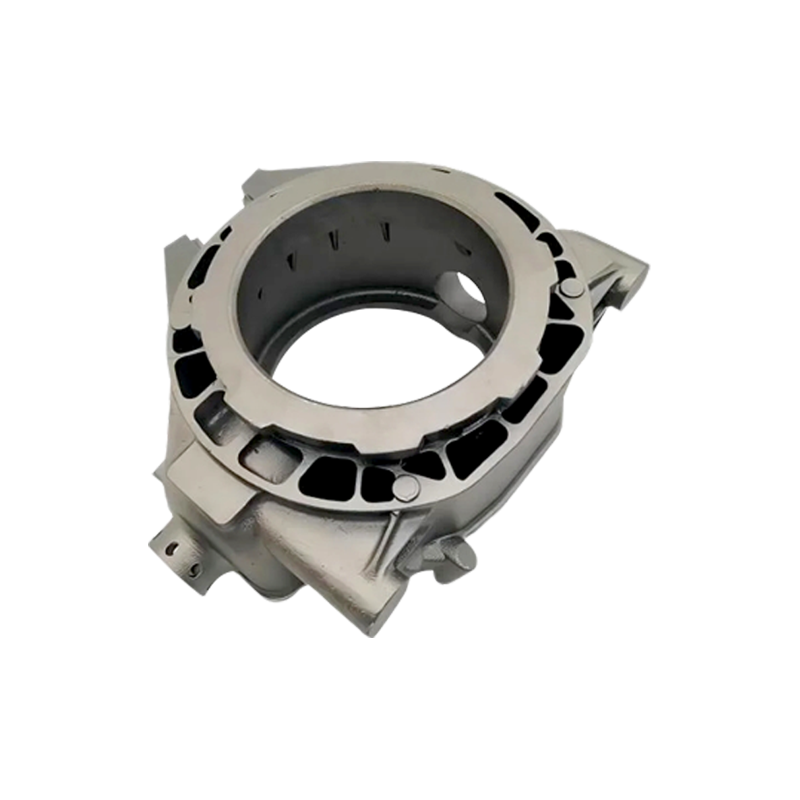

The design of the automobile exhaust manifold incorporates complex aerodynamic principles, and its internal structure often contains multiple curved flow channels, curved surfaces and interfaces to optimize exhaust gas flow and reduce resistance. CNC machining technology can easily handle these complex geometric challenges with its excellent programming flexibility and high-precision machine tools. By reading the three-dimensional model generated by the CAD/CAM system, CNC machine tools can accurately control the movement trajectory of the tool, and achieve one-to-one accurate reproduction of whether it is subtle surface changes or deep internal cavities. This high-precision machining ensures that the exhaust manifold can operate efficiently in complex engine environments, reducing back pressure and improving exhaust efficiency.

2. Strict standards of high precision and tolerance control

In the automotive industry, any slight dimensional deviation can lead to performance degradation or failure. CNC machining technology is known for its strict tolerance control capabilities, which can accurately control processing size and shape within the micron range. For exhaust manifolds, high-precision machining means each interface can perfectly match the engine and other exhaust system components, reducing air leakage and improving the overall sealing of the system. In addition, CNC Machining Car Exhaust Manifold can also ensure the dimensional stability of the exhaust manifold under different temperature and pressure conditions, extend its service life, and improve the overall performance and reliability of the engine.

3. Wide material adaptability and processing flexibility

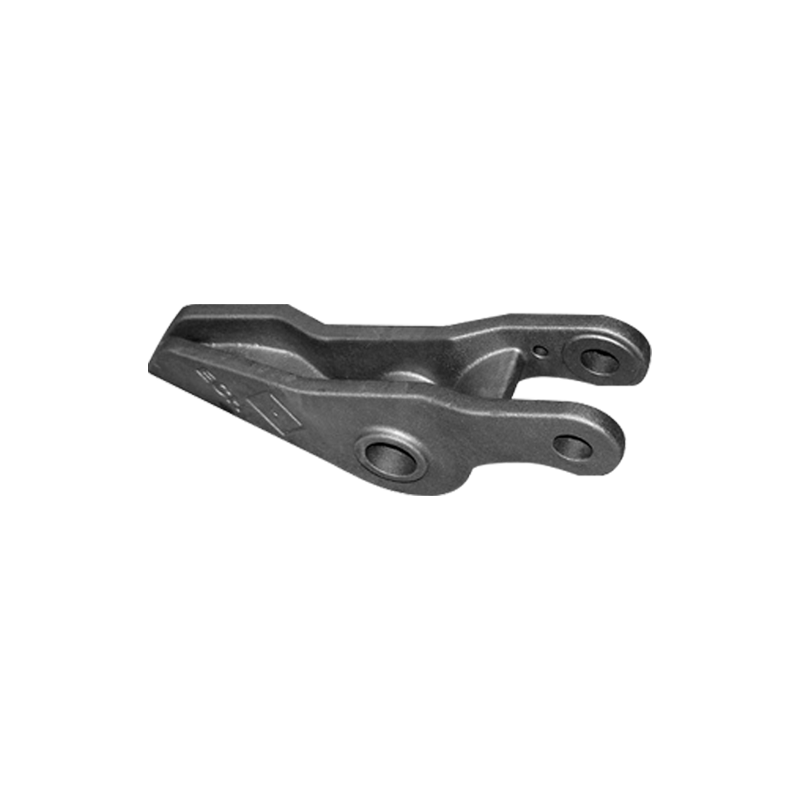

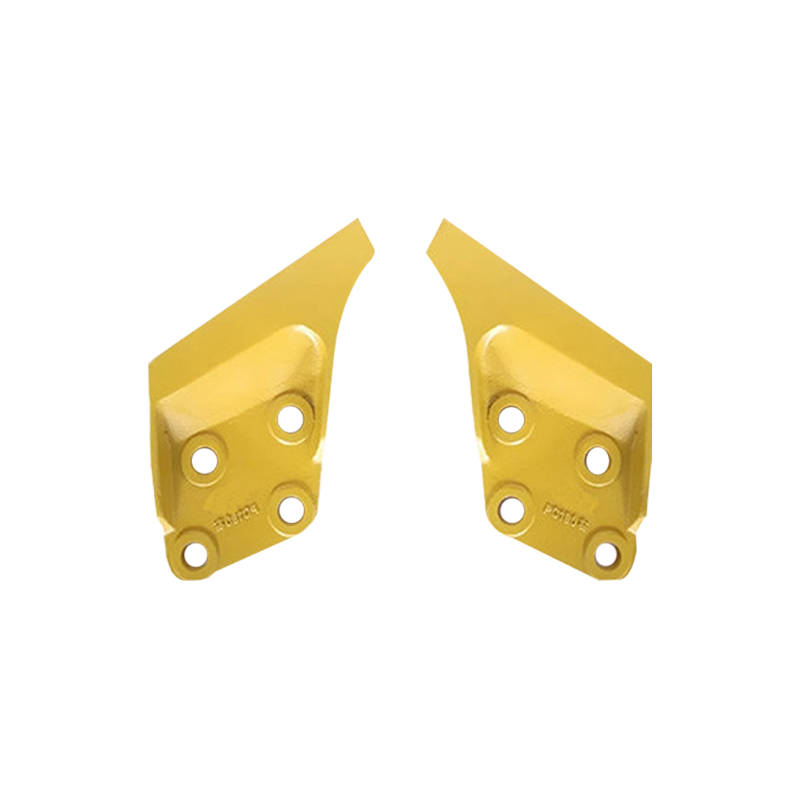

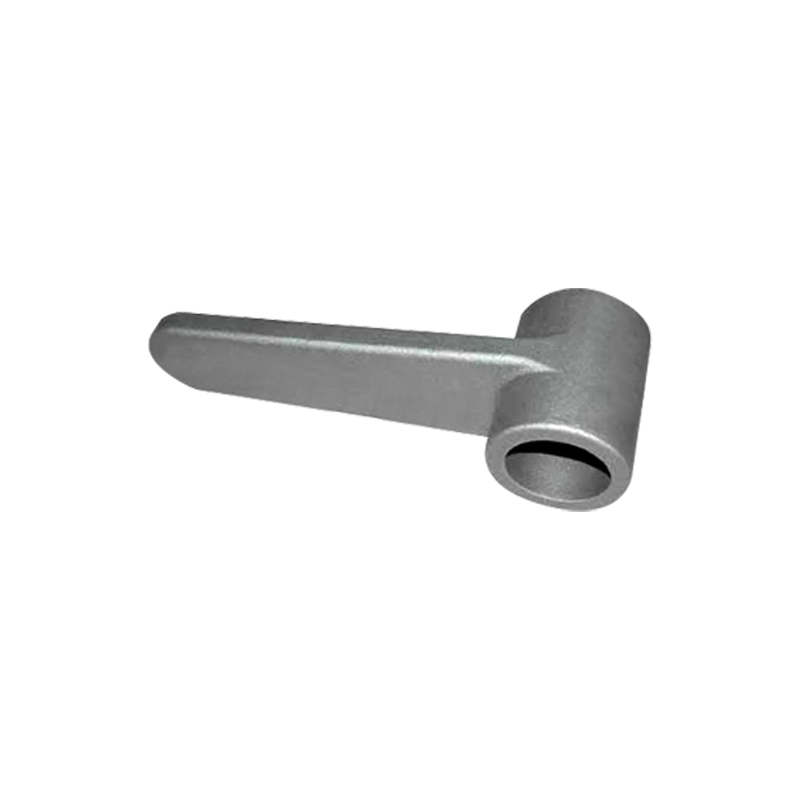

Automobile exhaust manifolds need to choose appropriate materials according to different engine types and working environments, such as cast iron, stainless steel, aluminum alloy, etc. Each of these materials has advantages and disadvantages and has different processing requirements. CNC machining technology is known for its wide material adaptability and can adjust processing parameters and tool selection according to different material properties to achieve precise and efficient processing. Whether it is hard cast iron or easily deformed aluminum alloy, CNC machine tools can easily handle it, ensuring that the processed exhaust manifold meets the design requirements and has excellent performance.

4. The perfect combination of customization and mass production

In the automotive manufacturing industry, market demands are diverse, requiring manufacturers to respond quickly and produce products that meet specific requirements. CNC machining technology meets this need with its flexibility and efficiency. Through programming and automated control, CNC machine tools can quickly switch between different processing programs and tool combinations to achieve customized production of exhaust manifolds of different specifications and models. At the same time, CNC processing can also meet the needs of mass production, reduce production costs and improve market competitiveness by optimizing the production process and improving production efficiency. This perfect combination of customization and mass production allows automakers to flexibly respond to market changes and meet the needs of different customers.

5. High degree of automation reduces human errors and improves production efficiency

The CNC machining process is highly automated, reducing errors and uncertainties caused by human operations. In the manufacturing process of exhaust manifolds, CNC machine tools can automatically complete the entire process from material clamping, processing to finished product blanking, without excessive manual intervention. This highly automated production method not only improves production efficiency, but also reduces the impact of human errors on product quality. By reducing the uncertainty caused by human factors, CNC machining ensures the consistency and stability of the exhaust manifold manufacturing process, improving product reliability and durability. At the same time, highly automated production methods also reduce labor intensity, improve the working environment, and increase employee job satisfaction and efficiency.

Language

Language

FT CASTING

FT CASTING