Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

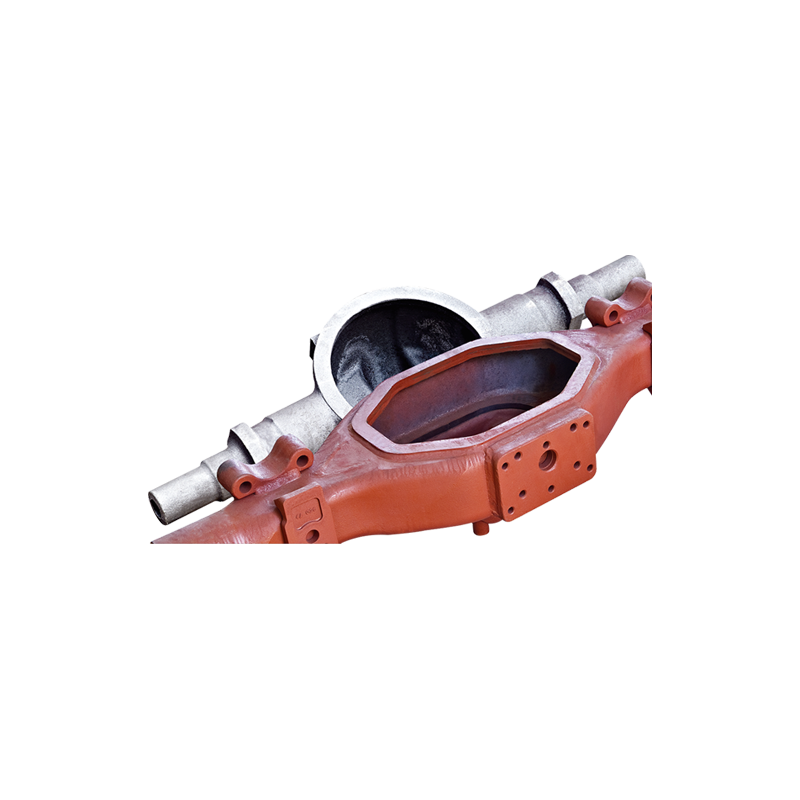

1. Structural design

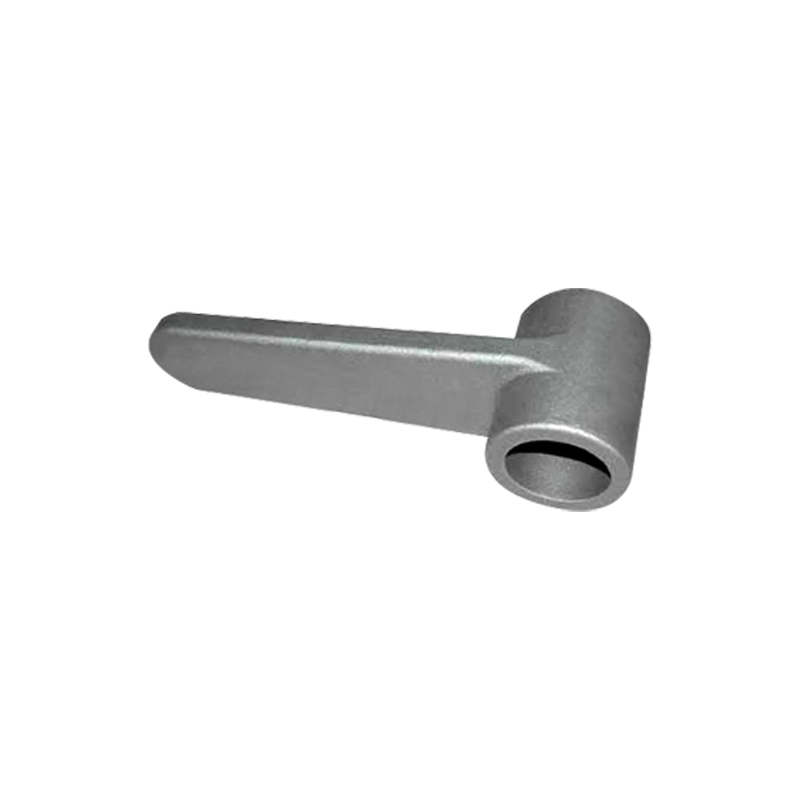

The structural design of the base shaft block is the cornerstone to ensure its functionality. At the beginning of the design, the load distribution, rotation speed and working environment of the bearing need to be analyzed in detail, and a stable and efficient support structure is built on this basis. The support surface is not only required to be flat and smooth, but also needs to achieve micron-level accuracy through precision machining technology to minimize friction with the bearing, improve rotation efficiency and extend service life. Considering the multi-directional forces and complex movements that the bearing may be subjected to, the structure of the base shaft block must also have sufficient rigidity and toughness to resist deformation and vibration. At the same time, the design should incorporate elements that are easy to maintain and repair, such as removable parts and windows for easy observation, so that quick repairs can be carried out when necessary.

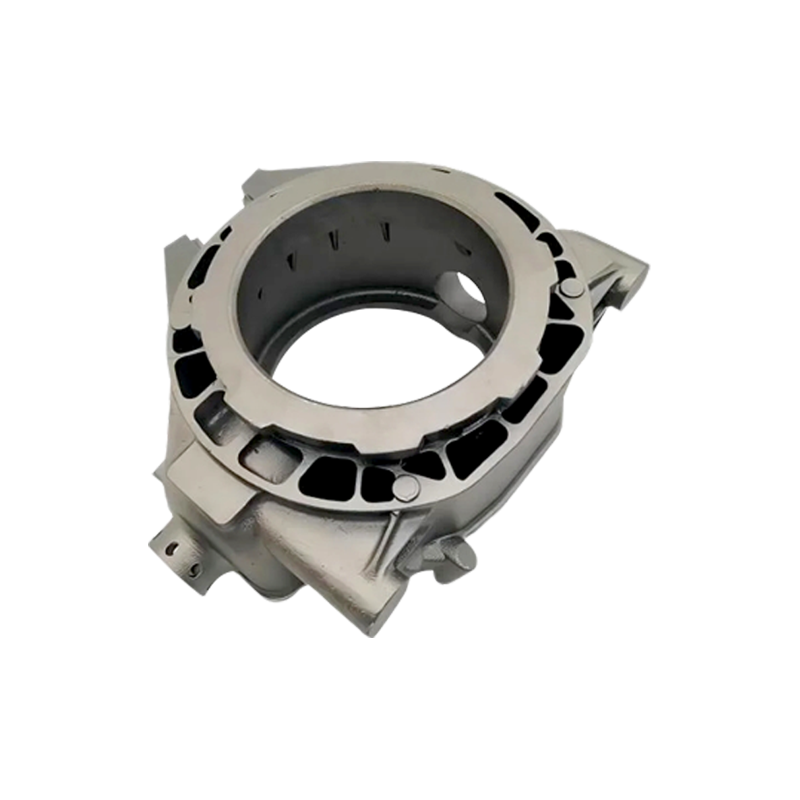

2. Material selection

Material selection is an important part of the base shaft block design that cannot be ignored. The ideal base shaft block material should have high strength, high wear resistance, good thermal stability and corrosion resistance. These characteristics ensure that the base shaft block can still maintain stable performance in harsh working environments and provide reliable support for the bearing. For example, for heavy-load and high-speed applications, high-strength alloy steel or cast iron materials can be used; for occasions where weight reduction is required, lightweight materials such as aluminum alloy can be selected. The cost-effectiveness of the material is also one of the factors to be considered when selecting, to ensure that the manufacturing cost is controlled while meeting the performance requirements.

3. Installation accuracy

The installation accuracy is directly related to the matching quality between the base shaft block and the bearing, which in turn affects the operating stability of the entire mechanical system. During the installation process, the operating procedures must be strictly followed to ensure that the base shaft block is accurately positioned. This includes the use of high-precision measuring tools for positioning detection, and the use of appropriate fastening methods and tools to ensure a firm connection between the base shaft block and the equipment foundation. In addition, attention should be paid to the cleanliness of the installation environment to avoid the influence of impurities and dirt on the installation accuracy. By strictly controlling the installation accuracy, it is possible to ensure that the bearing runs stably at the correct position and angle, reducing failures and maintenance costs caused by installation errors.

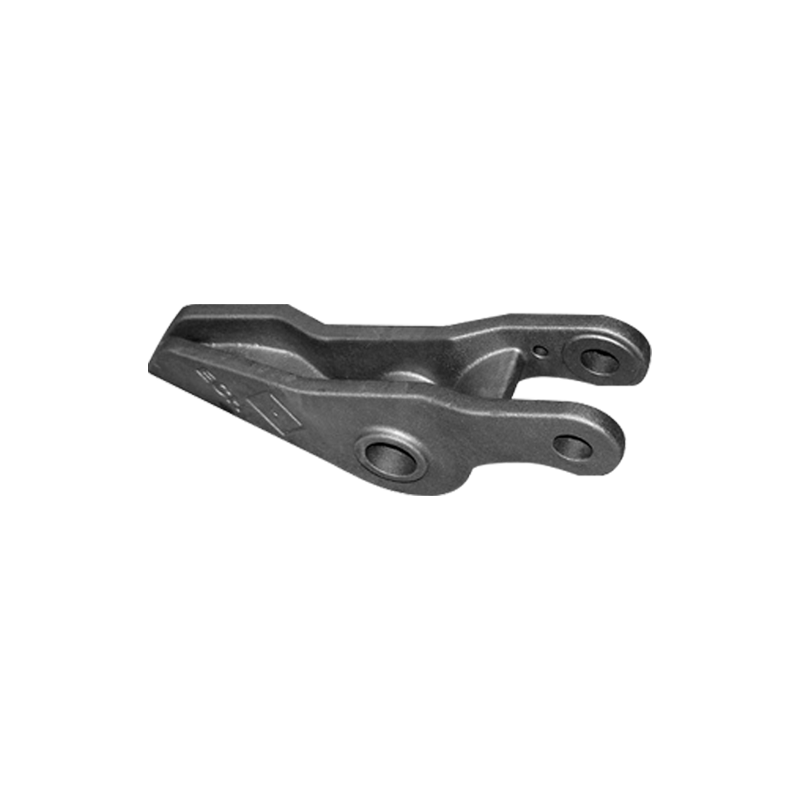

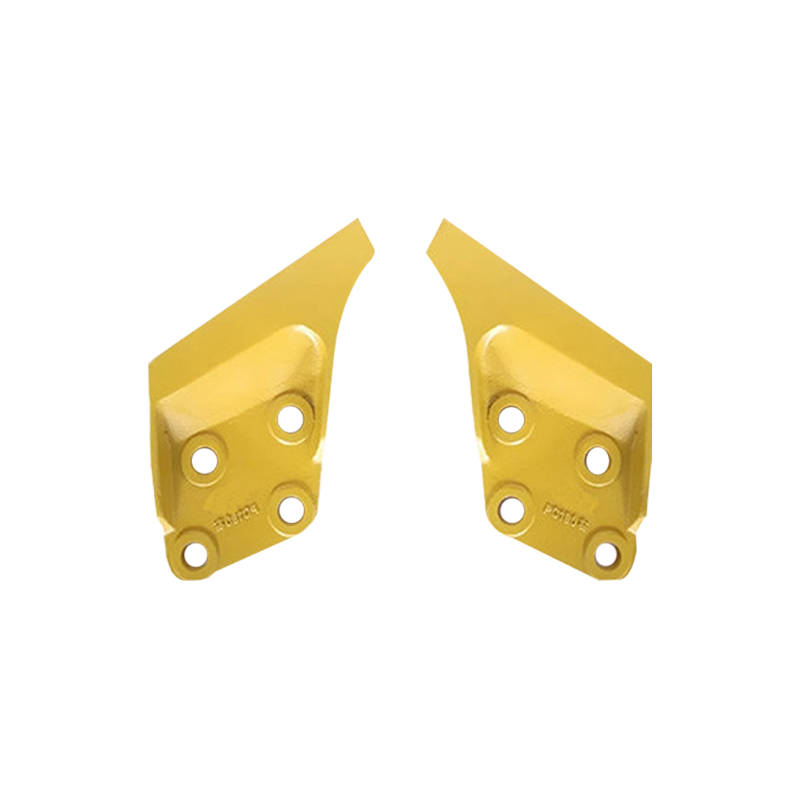

4. Synergy with other components

As an important component of the mechanical system, the performance of the base shaft block is also affected by the synergy with other components. During the design process, the interaction between the base shaft block and the bearings, transmission device, swing arm and other components must be fully considered. For example, when designing the transmission device, the transmission path and size of the transmission force must be considered to ensure that the base shaft block can withstand the corresponding load and remain stable; when designing the swing arm, the impact of the swing arm's motion trajectory and speed changes on the base shaft block must be considered to optimize the support structure and installation method. Attention should also be paid to the design of the lubrication and cooling system to ensure that the bearings operate in good working conditions and avoid failures and damage caused by overheating or poor lubrication. By comprehensively considering these factors and taking corresponding design measures, the synergy between the base shaft block and other components can be optimized, thereby improving the performance and reliability of the entire mechanical system.

Language

Language

FT CASTING

FT CASTING