Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

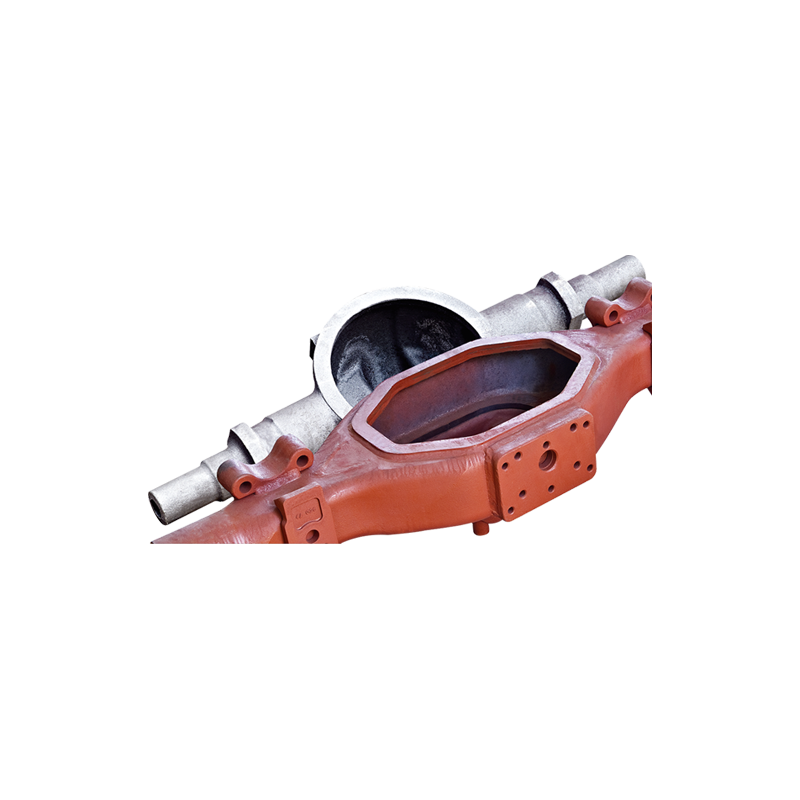

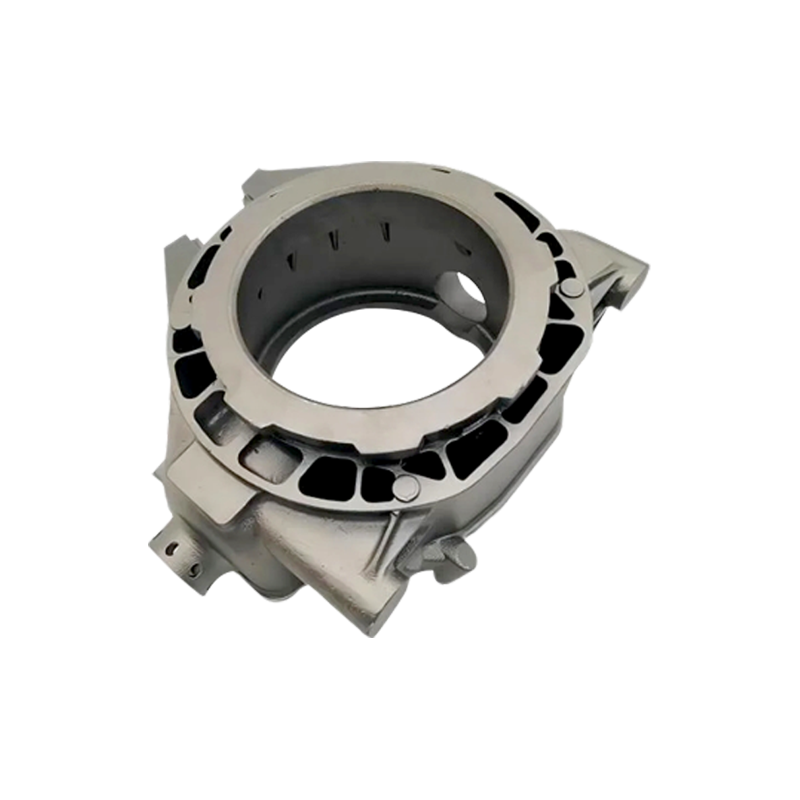

1. Bearing fixation

One of the core functions of the Base Shaft Block is to fix the bearing to ensure that it maintains the correct position and angle during the operation of the equipment. This function is critical for many mechanical equipment, especially in applications involving high-speed rotation or high loads. For example, in motors and pumps, the precise positioning of bearings can prevent excessive wear and failure. By providing a stable support platform, the Base Shaft Block can effectively reduce damage caused by vibration and displacement. A properly designed Base Shaft Block can also optimize lubrication performance, ensuring that the bearing is fully lubricated during operation, further extending its service life. For industrial production, the stability of the fixed bearing directly affects the efficiency and reliability of the equipment. Therefore, choosing the right Base Shaft Block is particularly important in equipment design and maintenance.

2. Multi-directional rotation

The design of the Base Shaft Block allows the bearing to rotate freely in multiple directions, which is particularly important in many modern mechanical systems. Especially in automation and robotics, equipment often needs to flexibly adjust its direction under different working conditions. For example, on an assembly line, robots need to be able to respond quickly and change operating angles to adapt to different assembly tasks. The multi-directional rotation capability of the Base Shaft Block enables these systems to operate efficiently and reduce downtime caused by mechanical limitations. This flexibility also enhances the system's adaptability, enabling it to maintain efficient performance in complex working environments. Therefore, Base Shaft Block not only improves the flexibility of mechanical equipment, but also improves the overall efficiency and competitiveness of the production line.

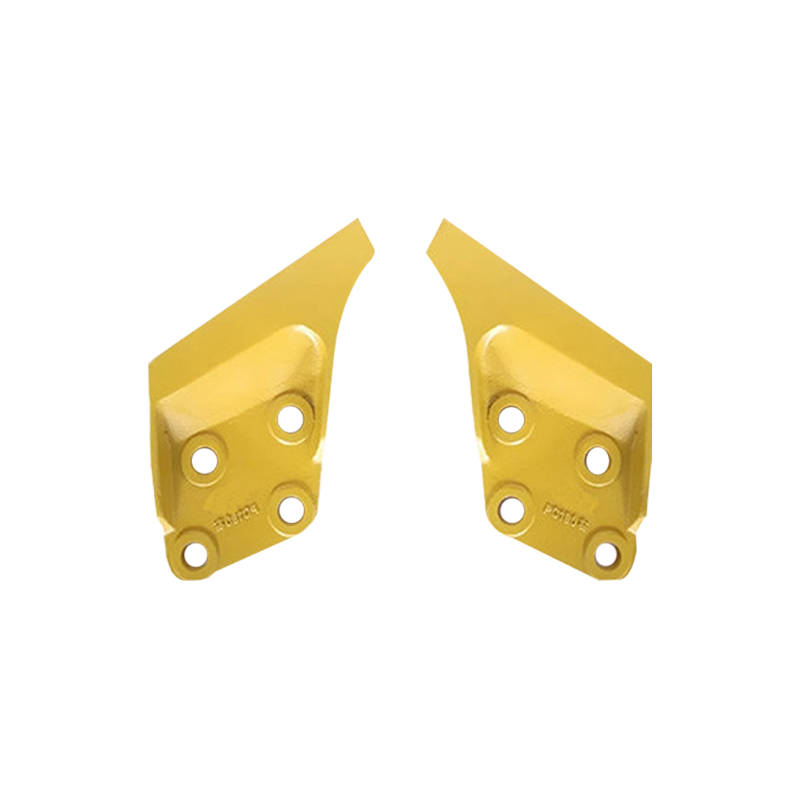

3. Support other mechanical components

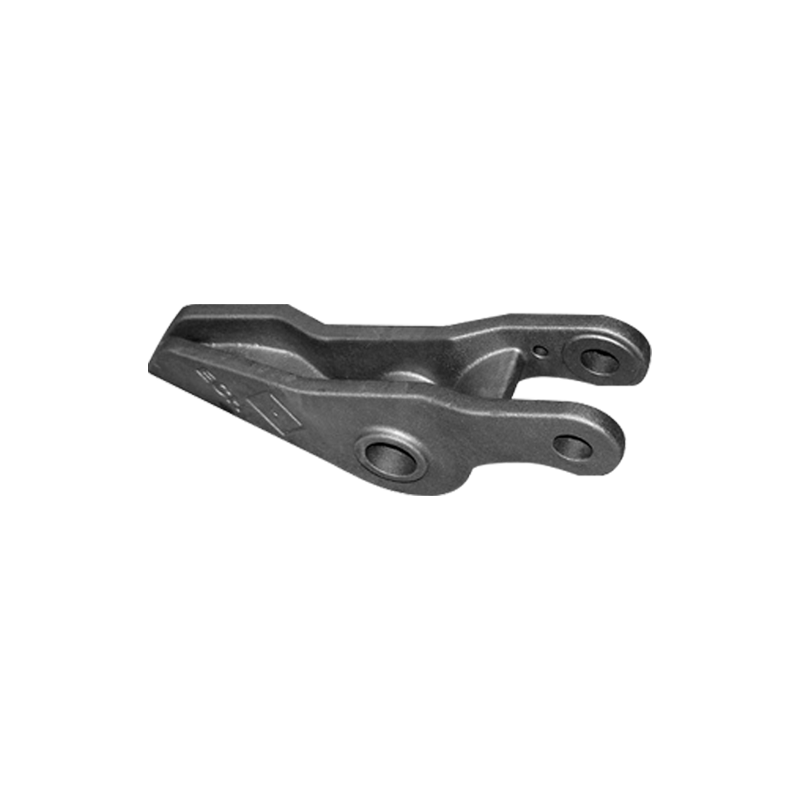

In addition to fixing bearings, Base Shaft Block is also widely used to support other mechanical components, such as transmissions and swing arms. This support capability is essential for the overall stability of the mechanical system. In many cases, the normal operation of the equipment depends on the coordinated work of multiple components. As a basic support, Base Shaft Block can ensure the reliability of these components during operation. For example, in transportation and conveying equipment, Base Shaft Block can support pulleys and chains to ensure that they run smoothly and avoid failures or damage caused by improper support. In addition, the strength and durability of Base Shaft Block can withstand load changes under various working conditions, thereby ensuring the long-term stable operation of the equipment. This support capability makes Base Shaft Block a key component in complex mechanical systems, ensuring that the various components can work together efficiently.

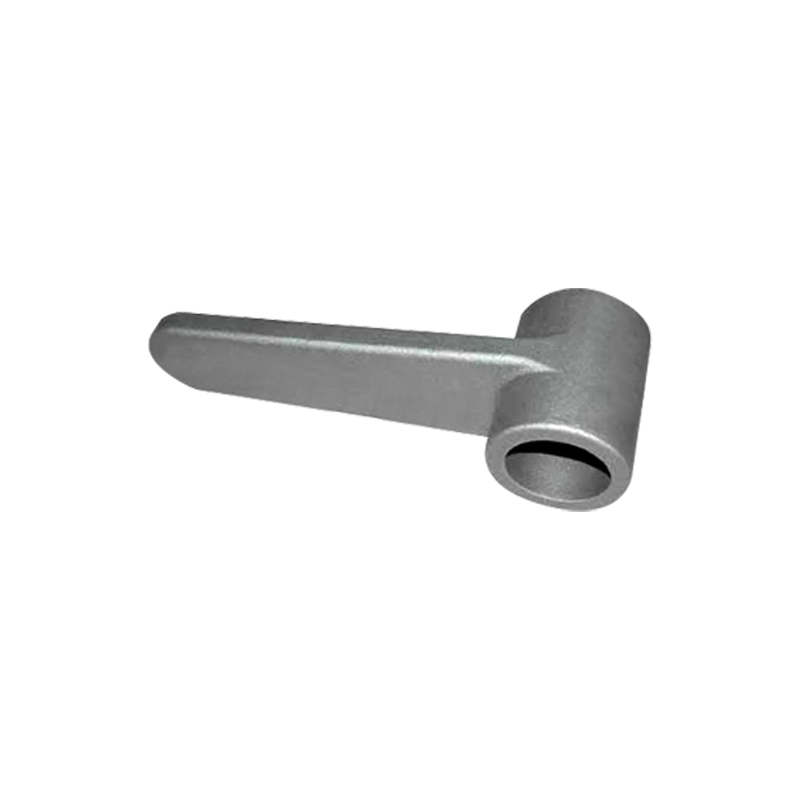

4. Convenient installation and removal

Base Shaft Block is usually designed to be simple, lightweight, and easy to install and remove, which is extremely important in the maintenance and replacement of modern mechanical equipment. In many industrial environments, equipment needs to be regularly inspected or replaced to ensure its optimal performance. Convenient installation and removal capabilities allow operators to complete related work in a short time, thereby reducing downtime. For example, on a production line, if a mechanical component fails, quickly replacing the Base Shaft Block can quickly resume production. This efficient maintenance process not only improves work efficiency, but also reduces economic losses caused by equipment failure. Especially in large-scale production environments, reducing downtime is the key to improving overall productivity, so the convenience of Base Shaft Block is particularly important in practical applications.

5. Application in various industrial fields

Base Shaft Block is widely used in many industrial fields, and its adaptability and functionality make it an indispensable component. In automotive manufacturing, Base Shaft Block is used to support engine components, transmission systems and suspension systems to ensure the stable operation of these key components. In the aerospace field, these components help ensure the efficient operation of complex mechanical systems in aircraft such as rudders and propulsion devices. In the manufacturing industry, Base Shaft Block is widely used in various mechanical equipment, such as CNC machine tools, conveying equipment and automated assembly lines, providing the required support and stability. With the continuous development of emerging technologies, the application scope of Base Shaft Block is still expanding, including wind turbines and solar energy equipment in the field of renewable energy. This wide range of applications makes Base Shaft Block play an increasingly important role in modern industry, promoting technological progress and production efficiency in various industries.

Language

Language

FT CASTING

FT CASTING