Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

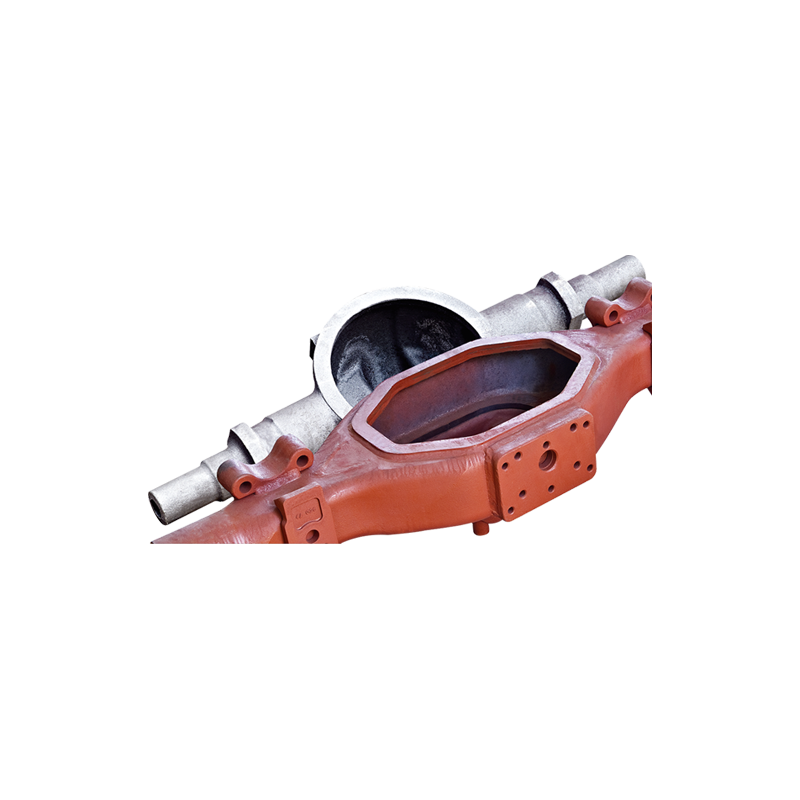

1. Connection and Fixation

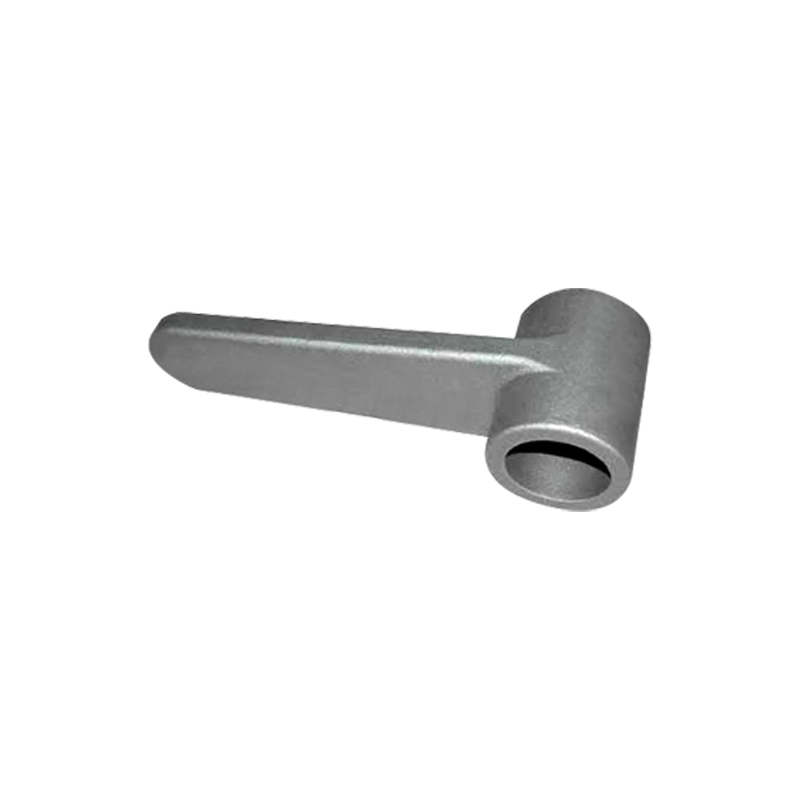

The basic function of Train Casting Steel Track Shackles is to serve as a connecting element to firmly connect different structural parts or equipment together. In the railway system, these shackles are often used to connect important components such as rails and sleepers, carriages and hooks. Their design ensures the stability of the connection points and reduces the risk of loosening or falling off due to movement. With strong pulling force and bearing capacity, shackles can effectively prevent accidental separation of trains during operation, thereby ensuring the safety of passengers and cargo. It is crucial to choose the right shackle model and specification, because different application scenarios may require different strength and flexibility. This connection and fixation function makes Train Casting Steel Track Shackles an indispensable part of railway engineering, ensuring the stability and safety of the entire transportation system.

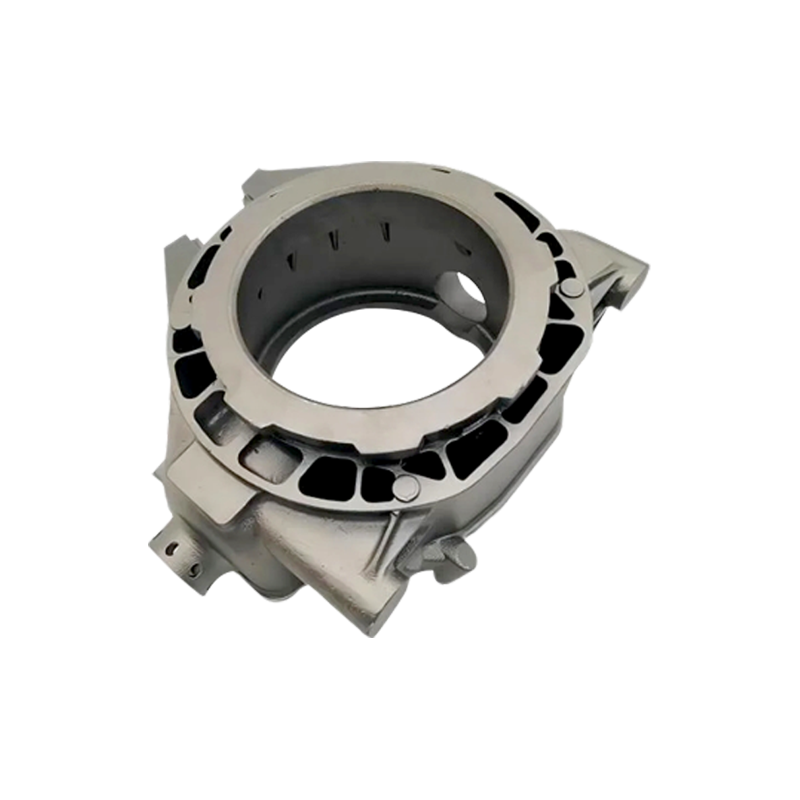

2. Load Distribution

Train Casting Steel Track Shackles can withstand heavy loads and effectively distribute the weight from trains or heavy equipment. This function is particularly important because the railway system is faced with huge pressure and weight, especially when long freight trains pass through. By distributing the load evenly, shackles can prevent local overloads, reduce the risk of structural damage, and extend the service life of the entire system. Specifically, shackles can transfer vertical and horizontal loads from the train to the track and supporting structure, reduce local stress concentration, and prevent damage caused by fatigue or corrosion. This load distribution capability is even more critical in harsh climate conditions or when passing through uneven tracks. Proper load distribution not only helps improve the safety of rail transportation, but also reduces maintenance costs and ensures long-term efficient operation.

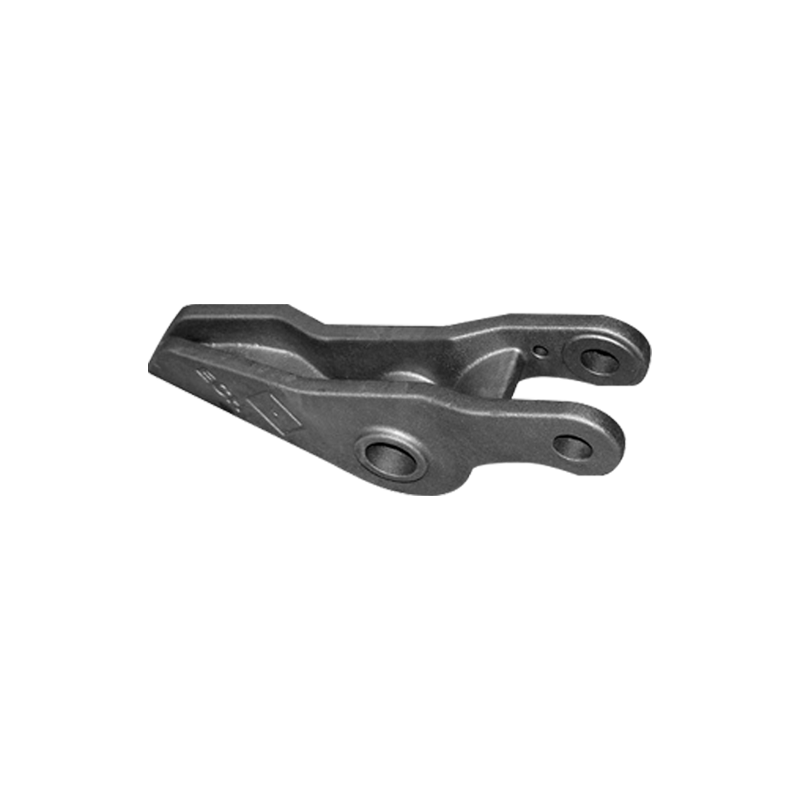

3. Provide flexibility

The design of Train Casting Steel Track Shackles allows necessary flexibility in certain situations, which is essential for rail transportation. This flexibility helps ensure stable operation of vehicles when trains turn, tilt or go through unstable tracks. For example, the hinged design of shackles can adapt to changes in the track, so that the train will not be damaged by sudden turns or uneven tracks during operation. This feature not only helps protect the safety of trains and their passengers, but also reduces wear and tear on equipment and extends its service life. Flexibility is also reflected in the ability of connected components to be adjusted and maintained at any time, allowing operators to quickly respond to changes in track and train operation. Through this adaptability, Train Casting Steel Track Shackles can play an important role in complex railway systems.

4. Easy installation and removal

Train Casting Steel Track Shackles are designed to be easy to install and remove, which is essential for railway maintenance and overhaul. Since railway systems require regular inspection and maintenance, being able to quickly replace or repair shackles will greatly improve work efficiency. This convenience not only reduces downtime, but also reduces maintenance costs. In actual applications, operators can quickly replace or adjust the shackle with simple tools and a few steps. In addition, this design allows for quick response and resolution of problems in the event of sudden failures, ensuring the safety of train operation. The convenient installation and removal features make Train Casting Steel Track Shackles an important part of efficient railway operations and support the smooth operation of railway transportation.

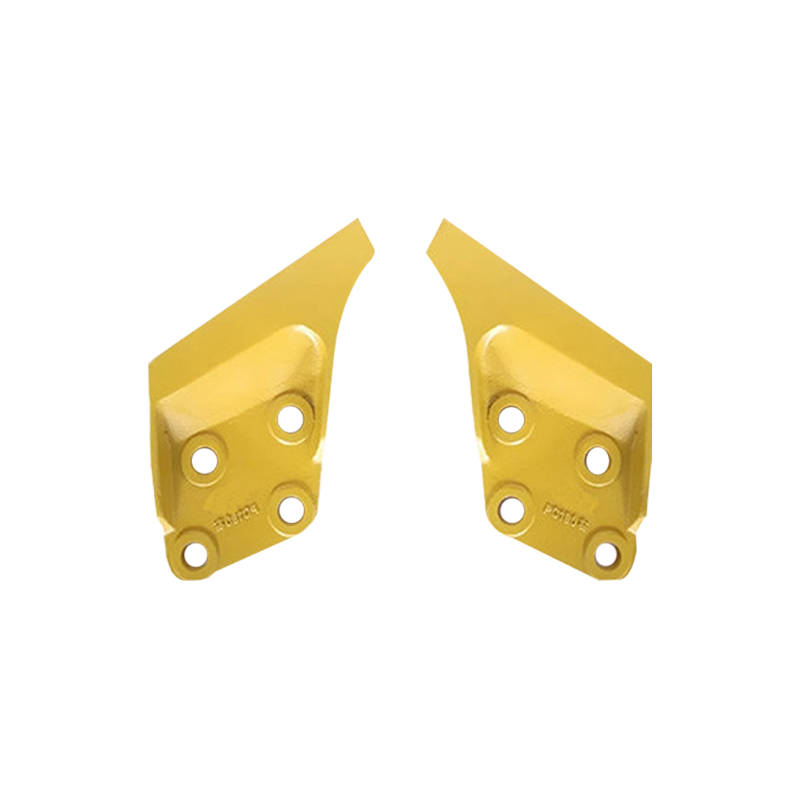

5. Corrosion and wear resistance

Train Casting Steel Track Shackles are usually made of high-strength cast steel materials with good corrosion resistance and wear resistance. This feature ensures their long-term use in various harsh environmental conditions, such as exposure to rain, salt spray and other corrosive substances. Corrosion-resistant materials not only extend the service life of shackles, but also reduce the risk of failures caused by environmental factors. Wear-resistant properties enable these shackles to maintain good performance in high-load, high-frequency operations, reducing the frequency of replacement due to wear. This durability provides reliable support for railway systems and reduces the complexity and cost of maintenance. Regular material and performance inspections help to detect potential problems in a timely manner, ensure that the equipment operates in optimal conditions, and further improve the safety of overall operations.

6. Compliance with safety standards

Train Casting Steel Track Shackles follow strict safety standards during design and manufacturing to ensure that they can still work reliably under extreme conditions. Safety requirements for railway equipment vary from country to country and region to region, but most require shackles to meet specific standards in terms of load-bearing capacity, fatigue strength and corrosion resistance. This compliance not only protects staff and passengers in railway operations, but also provides a guarantee for maintaining the stability of the entire transportation system. Regular quality inspections and certification procedures ensure that shackles always meet the latest industry standards. Manufacturers usually provide detailed instructions for use and safety data sheets to guide users to properly operate and maintain the equipment. By following these safety standards, Train Casting Steel Track Shackles can effectively reduce the risk of accidents and provide important safety guarantees for railway transportation.

Language

Language

FT CASTING

FT CASTING