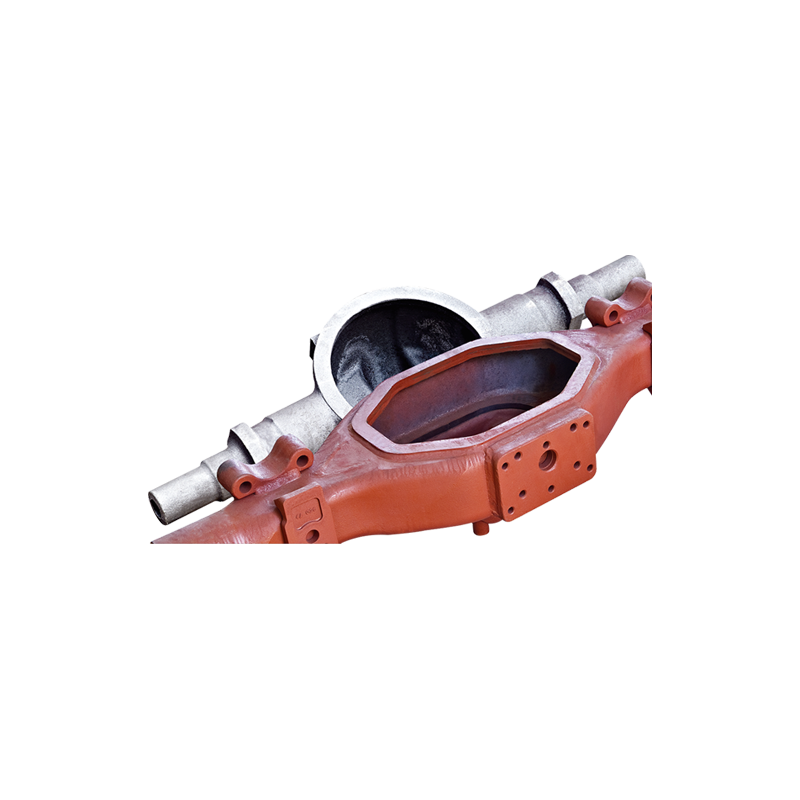

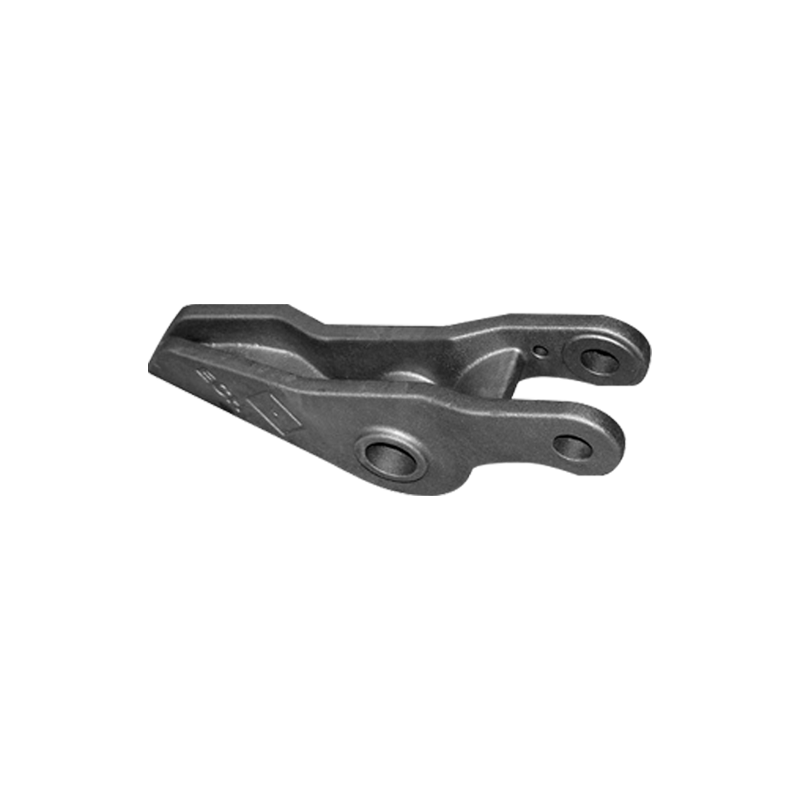

Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

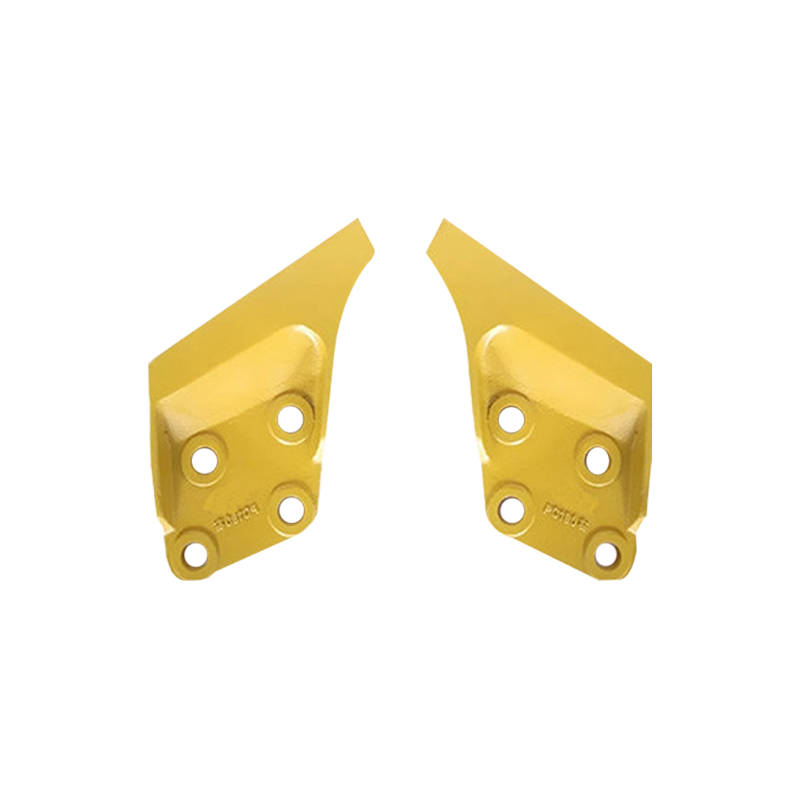

Agriculture Machine Casting Steel Parts

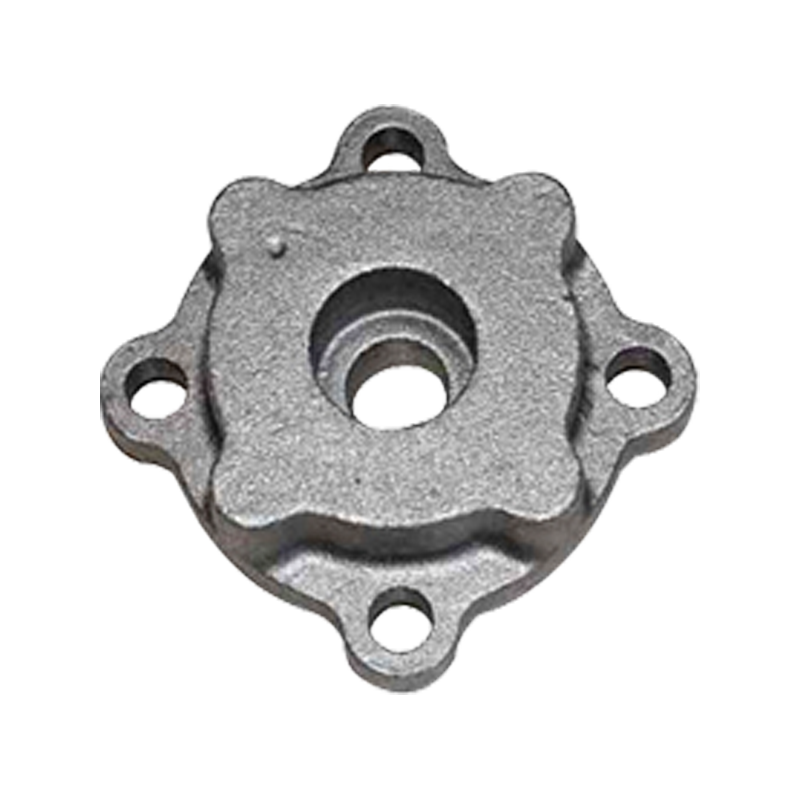

Agriculture Machine Bearing Bracket

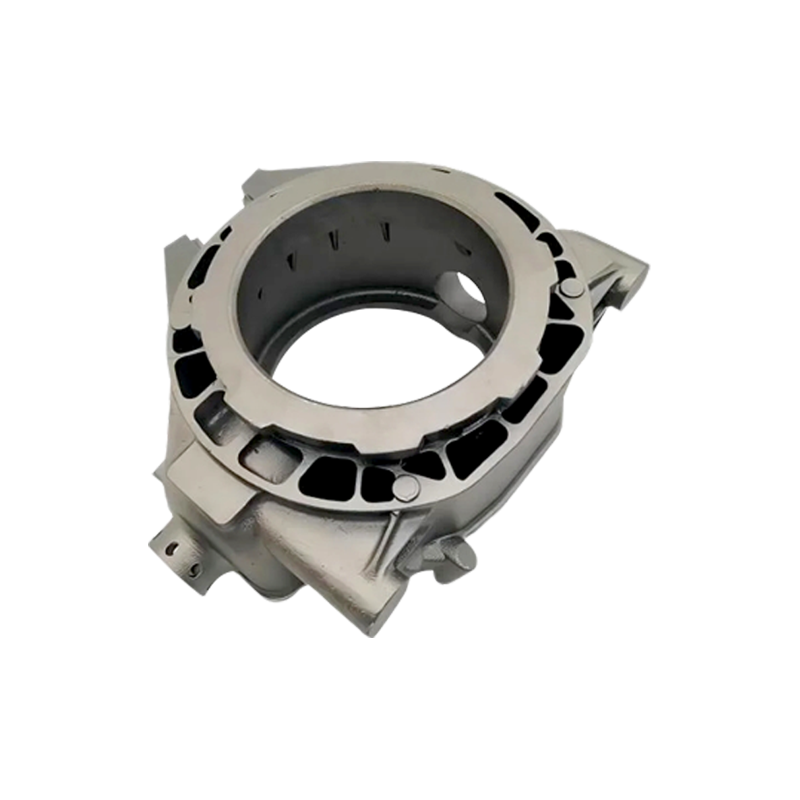

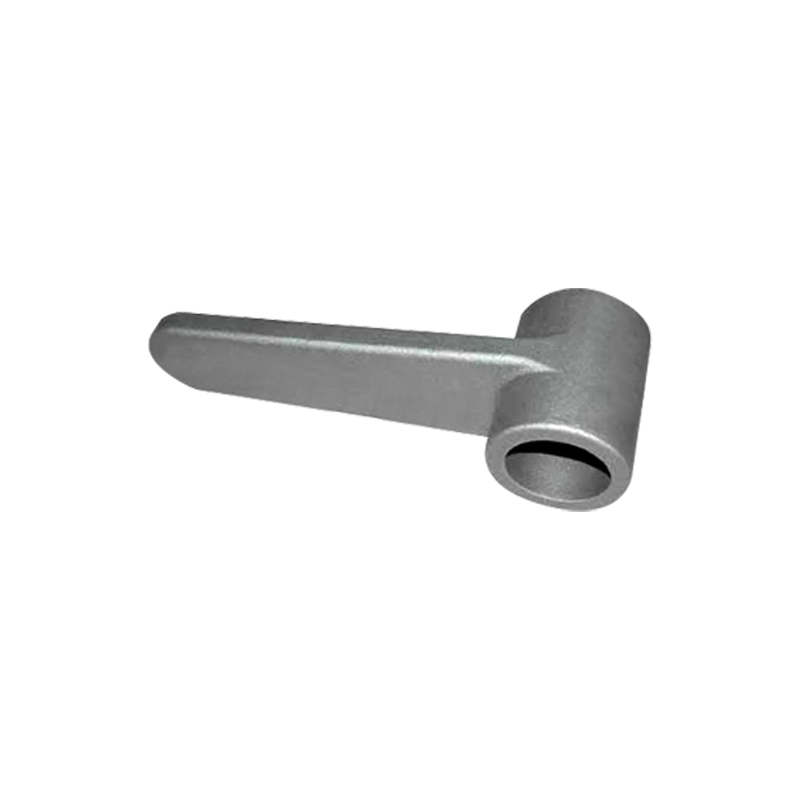

Bearing brackets are key components used to support and secure bearings. They are typically made of cast steel (such as cast carbon steel and low-alloy steel) and offer high load-bearing capacity, wear resistance, and corrosion resistance. The following is a detailed description:

Material and Classification

Cast steel brackets belong to the cast alloy category and are categorized by application: cast carbon steel, low-alloy steel, and specialty steel. These materials meet the strength and durability requirements of agricultural machinery. For example, the cast steel brackets for double-row tapered roller bearings in tractor transmissions achieve a balance between high load capacity and low energy consumption through optimized design.

Function and Application

Bearing brackets primarily provide support and positioning, ensuring bearing stability during operation. For example:

Bearing brackets in tractor transmissions utilize annular washers for clearance adjustment and optimized installation space.

Drill seed drill bearings utilize a triple seal structure to withstand dusty environments and extend life.

Disc harrow brackets utilize nitrile rubber seals for reliable performance despite direct soil contact.

These brackets are widely used in agricultural machinery components such as transmissions, drivetrains, and chassis. Different alloy ratios are used to meet load-bearing, wear, and corrosion resistance requirements.

Language

Language

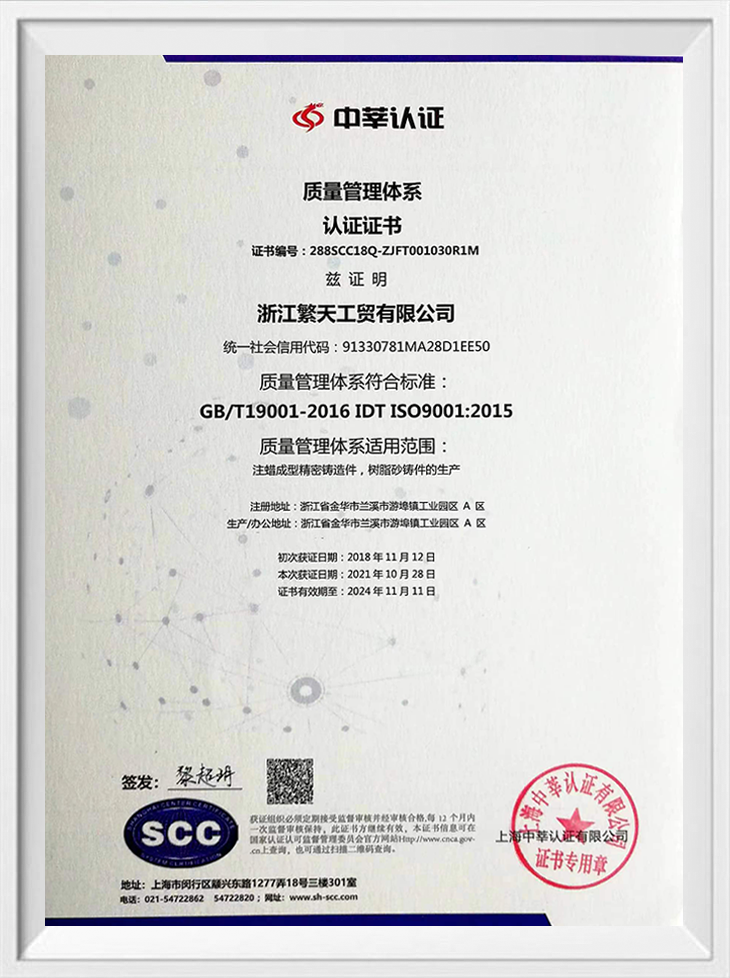

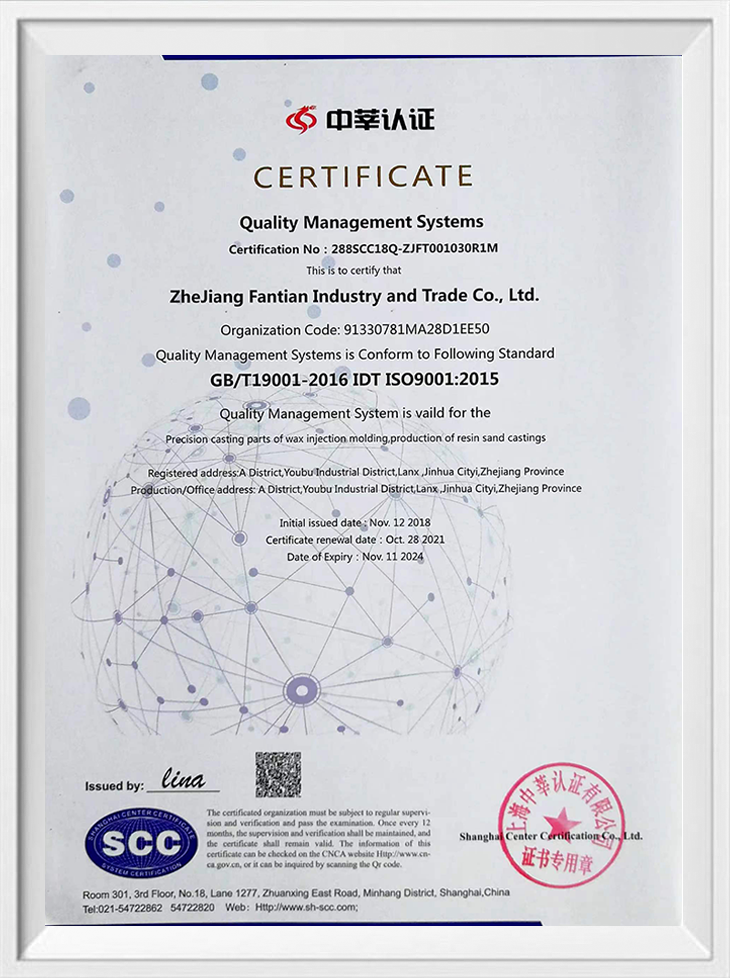

FT CASTING

FT CASTING