Zhejiang Fantian Foundry & Trading Co., Ltd., founded in 2000, specializes in the casting and processing of various carbon steel, alloy steel, ductile iron, nonferrous metal, stainless steel, and other materials and is proficient at investment casting and resin sand casting.

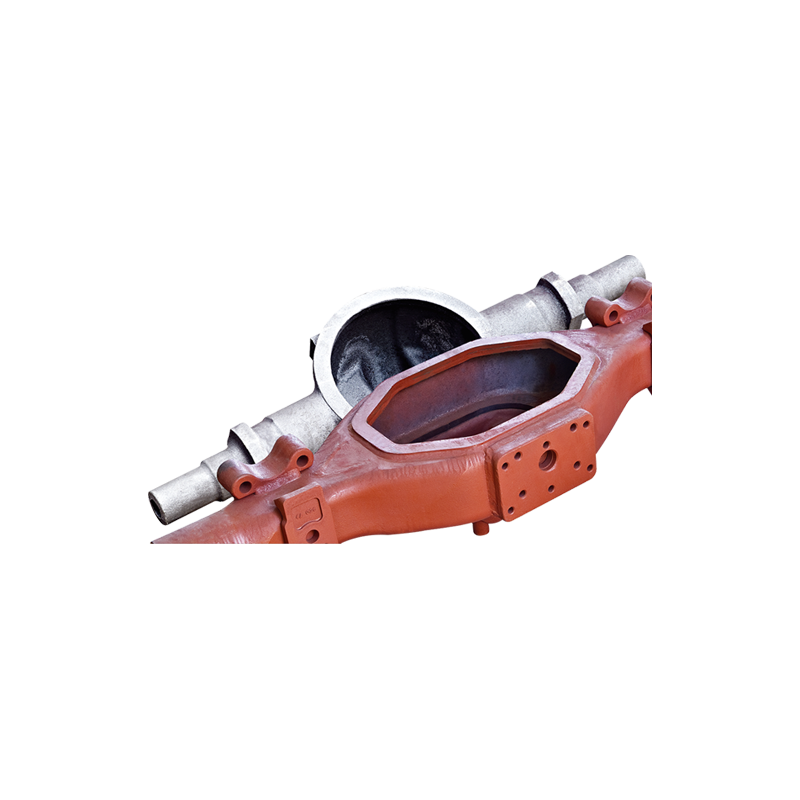

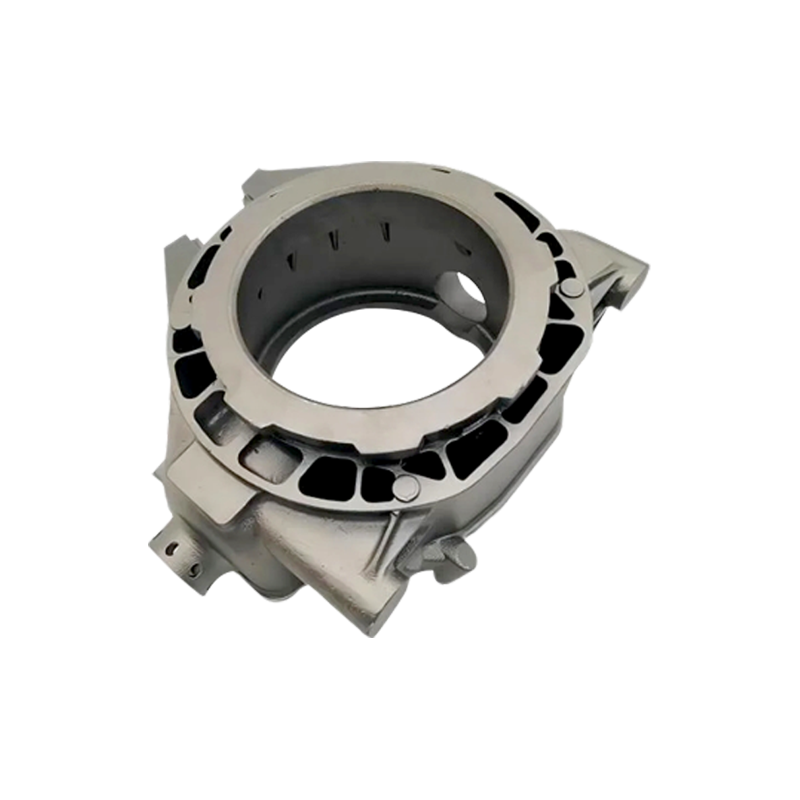

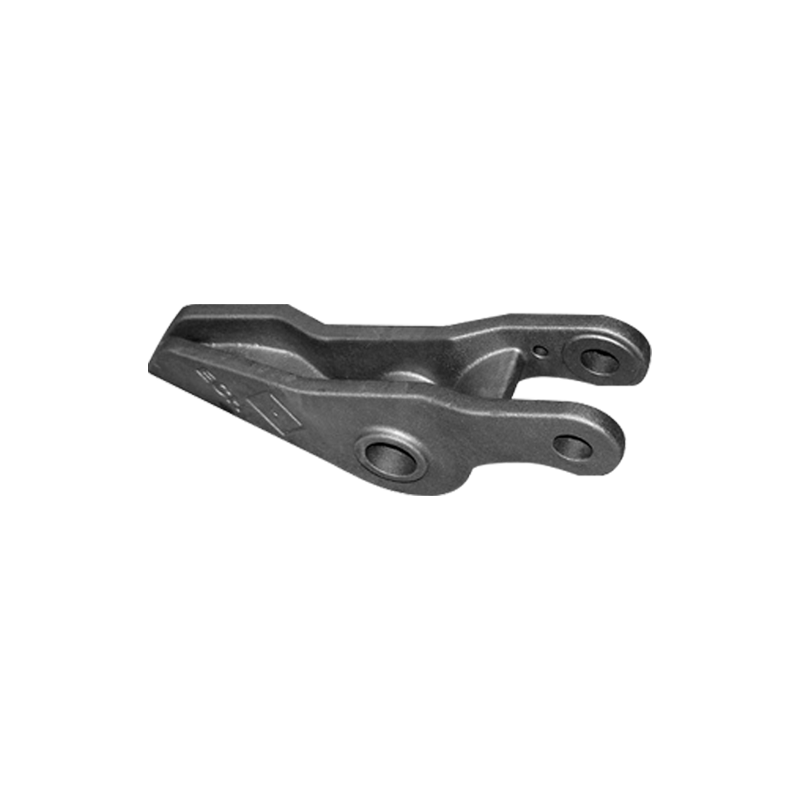

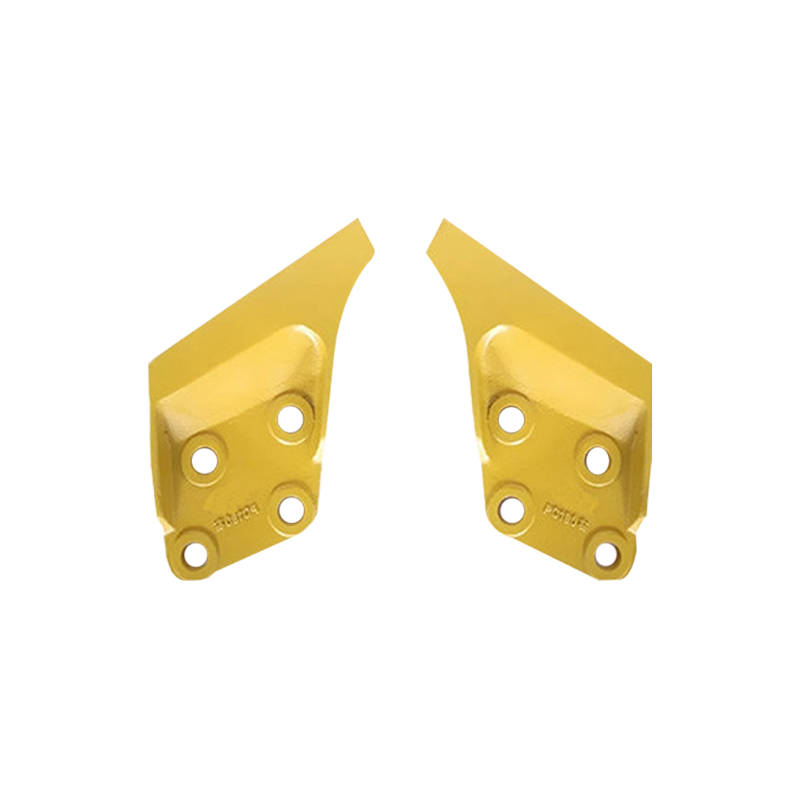

Situated in an economically developed area, our company enjoys convenient transportation and is one of China’s largest foundries. Our company covers an area of 110,000 m2 and has a sta of 320, including over 15 junior and senior technicians and 28 full-time inspectors. With an annual productivity of 12,000 tons, we mainly cast and process auto parts, motorcycle parts, railway parts, ship and wharf spreader accessories, agriculture machinery parts, construction machinery parts, and other high-quality and high-precision metal parts. Our products are mainly sold in the USA, Canada, Germany, Britain, France, Austria, Japan, Australia, South America, Malaysia, and some domestic markets.

Our main production equipment includes 20-ton sand mixers, molding machines, 5-ton intermediate frequency furnaces, box-type heat treatment furnaces, shot blasting machines, vertical machining centers, horizontal machining centers, boring machines, lathes, drilling, and milling machines, etc.

Our main testing equipment includes: Direct-reading spectrometers, metallographic analyzers, X-ray inspection equipment, ultrasonic flaw detectors, mechanical property testing machines, impact testing machines, Brinell hardness testers, magnetic particle inspection machines, etc.

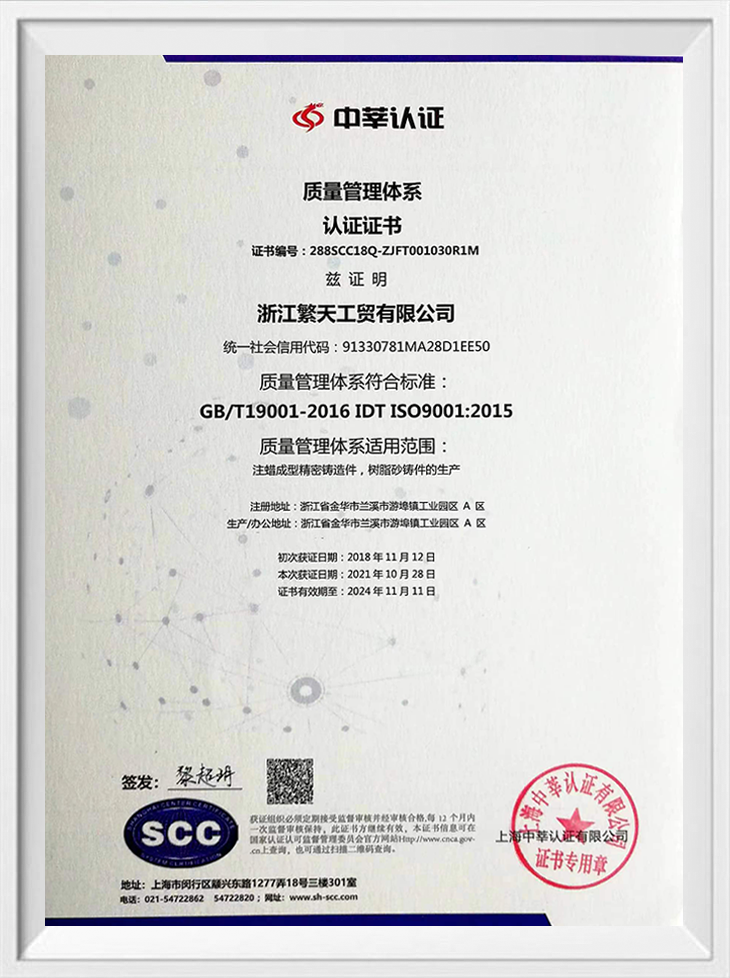

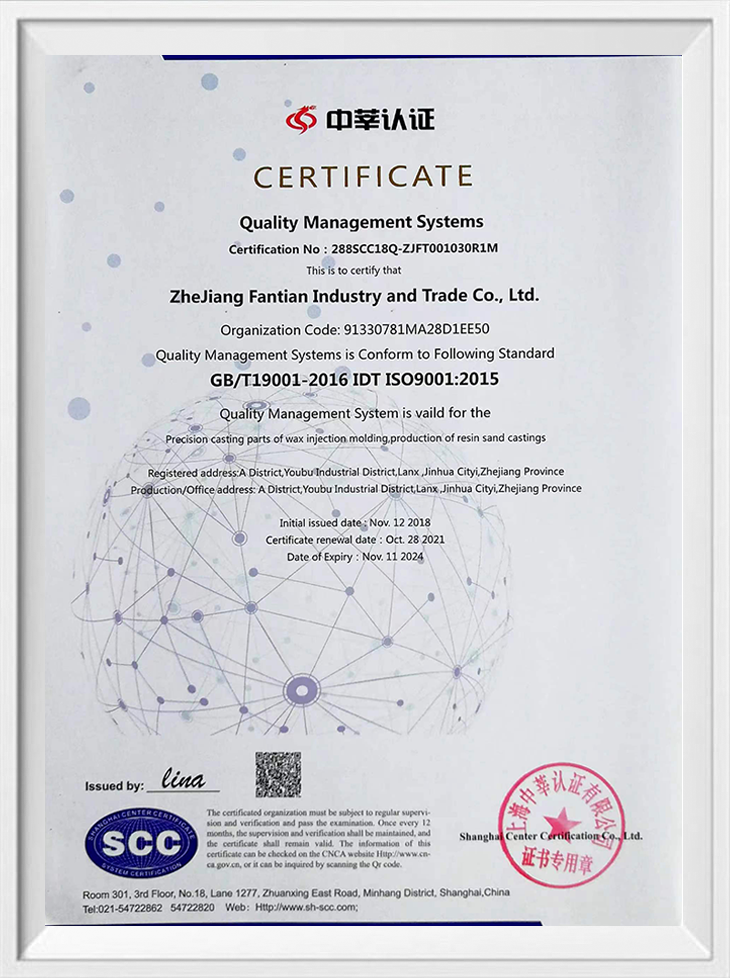

We always adhere to the tenet of “Sustainable Development, Better and Stronger”, the spirit of “United, Pragmatic, Innovative” and the quality policy of “Quality orientation, Constant Improvement, Constant Innovation, Customer First”, develop and make progress continuously. We began to implement ISO9001:2008 and ISO/TS 16949:2002 in August 2008.

Under the leadership of our General Manager, Mr. Xu Jianhua, we always seek to make quality products. In the principle of “Adapt to Market Demand, Meet Customer Needs, Perfect Management System, Make Technological Innovation”, all our employees unite together and strive to serve society by making top-quality and high-performance products at competitive prices.

Language

Language

FT CASTING

FT CASTING